Zeiss Surfcom Flex 50A Surface Roughness Measuring – Zeiss Surfcom / Seimitsu – 625006-9066-000 / Flex-50A / 50-A

Please use the request form to start a calibration services quote. You may also request equipment sales or repair services.

| Service & Purchase | Preise |

|---|---|

| Standard calibration to manufacturers specifications. | Inquire for pricing |

| Calibration including pre and post calibration data. | Inquire for pricing |

| Calibration with 17025 accreditation. | Inquire for pricing |

| Equipment repair to manufacturers specifications. | Inquire for pricing |

Beschreibung

The Zeiss Surfcom Flex 50A is an advanced surface roughness measuring instrument developed by Zeiss Surfcom in collaboration with Seimitsu, known for its precision and versatility in assessing surface quality in industrial settings. Here are the key specifications of the Zeiss Surfcom Flex 50A:

- Measurement Parameters: The Surfcom Flex 50A measures essential surface roughness parameters such as Ra (average roughness), Rz (mean roughness depth), Rq (root mean square roughness), Rt (maximum peak-to-valley height), Rmax (maximum roughness depth), and others according to international standards like ISO and ANSI.

- Measurement Range: It offers a wide measurement range suitable for various surface textures and profiles, typically ranging from sub-micrometer levels to several micrometers, ensuring versatility in measuring different types of workpiece surfaces.

- Probe System: Equipped with a highly sensitive stylus probe or non-contact probe, the instrument accurately traces surface contours and detects fine irregularities, providing precise surface roughness measurements.

- Flexibility: The Surfcom Flex 50A is designed for flexibility, allowing users to choose between a range of probes, including skidded and skidless probes, based on the specific measurement requirements and sample characteristics.

- Evaluation Length: Users can adjust the evaluation length or cutoff length to determine the sampling length for calculating roughness parameters, enabling customization of surface texture analysis based on application needs.

- Measurement Modes: The instrument supports various measurement modes such as vertical scanning mode, horizontal scanning mode, and combination modes, providing users with options to select the most suitable mode for their surface measurement tasks.

- Analysis Software: Accompanied by dedicated analysis software, the Surfcom Flex 50A offers advanced data processing capabilities, graphical representation of surface profiles, statistical analysis of roughness parameters, and customizable reporting features for comprehensive surface quality analysis.

- Accuracy and Repeatability: The Zeiss Surfcom Flex 50A delivers high measurement accuracy and repeatability, ensuring reliable and consistent surface roughness measurements essential for quality control and manufacturing processes.

- User Interface: Features an intuitive user interface with a touchscreen display or control panel, user-friendly menus, measurement presets, and real-time measurement feedback, facilitating ease of operation and efficient data acquisition.

- Data Management: The instrument allows for data storage and retrieval of measurement results, setups, and calibration data, promoting traceability, documentation, and comparison of surface roughness data over time.

- Calibration and Maintenance: Regular calibration, maintenance, and verification are recommended to maintain measurement accuracy and performance, with calibration procedures and service guidelines provided by Zeiss Surfcom and Seimitsu for optimal functionality.

- Application: The Zeiss Surfcom Flex 50A is suitable for a wide range of industries and applications including automotive, aerospace, medical devices, precision engineering, metalworking, semiconductor manufacturing, and surface coating industries where precise surface finish evaluation is critical for product quality and performance assessment.

In summary, the Zeiss Surfcom Flex 50A Surface Roughness Measuring instrument offers advanced surface roughness measurement capabilities, flexibility, accuracy, and user-friendly operation, making it a valuable tool for quality assurance, research, and development in various manufacturing and engineering fields.

Produktsuche

Laboratory Calibration

Micro Precision operates 36 laboratories globally providing reliable localized support

- Certified metrologists staffing laboratories in North America, Central America, South America, Europe, Asia, and the Middle East

- Comprehensive scopes of accreditation to meet a broad range of customer needs

- Expedited calibration services available

- Pickup and delivery services available

- Environmentally controlled facilities to ensure high quality and accurate calibrations and measurements.

Laboratory Calibration

Micro Precision operates 36 laboratories globally providing reliable localized support

- Certified metrologists staffing laboratories in North America, Central America, South America, Europe, Asia, and the Middle East

- Comprehensive scopes of accreditation to meet a broad range of customer needs

- Expedited calibration services available

- Pickup and delivery services available

- Environmentally controlled facilities to ensure high quality and accurate calibrations and measurements.

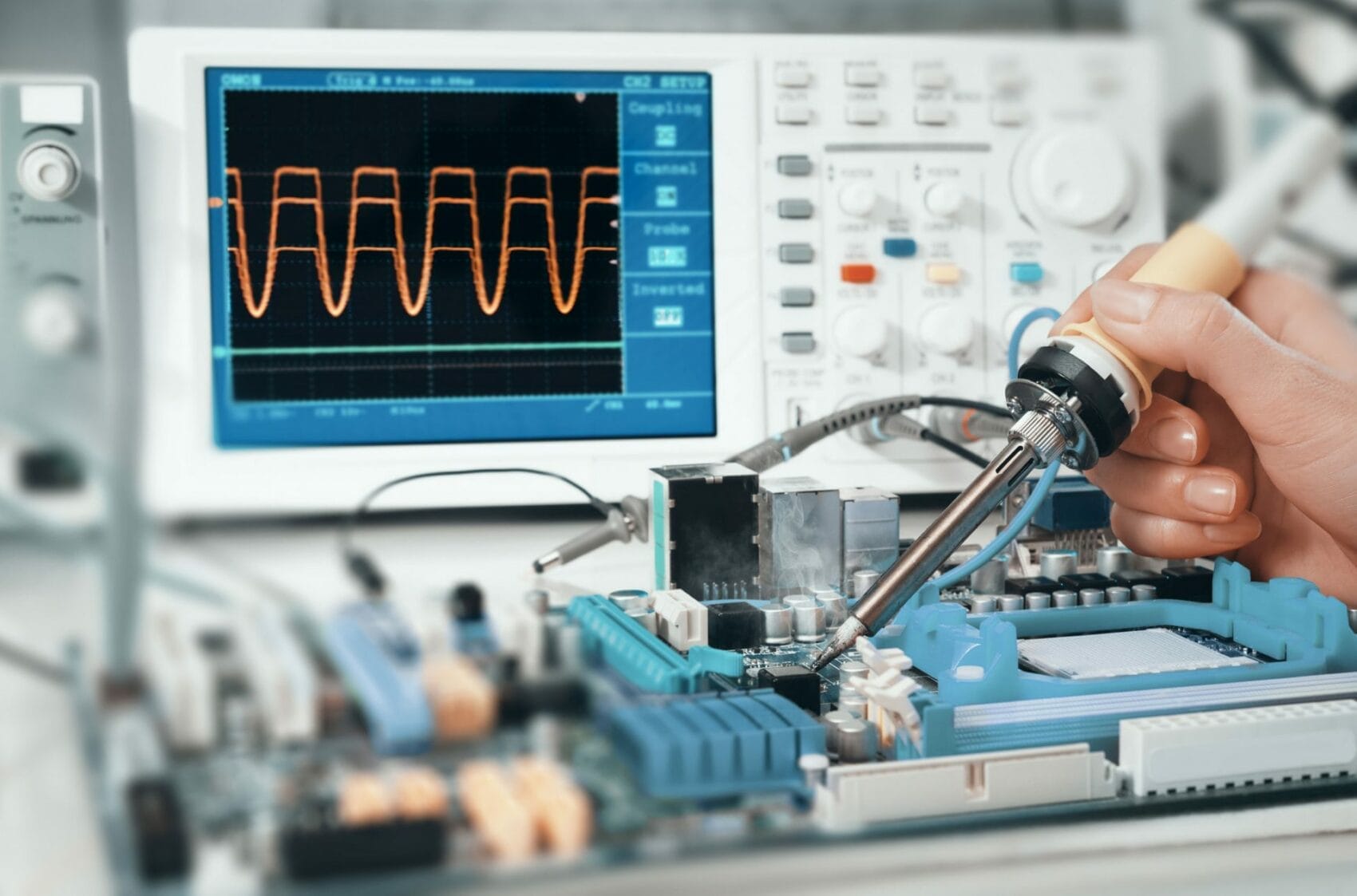

Quality Certified Test Equipment Repair Services

When a piece of equipment fails you have the option to repair or replace that item. Oftentimes repair is an economical and efficient solution. Micro Precision’s repair offering provides advantages to our customers:

- Cost effective; often less than OEM

- Efficient; often much better turn-time than the OEM

- Flexibility; willingness to work with customers to meet their needs

- Warranted repairs

- Ability to service many obsolete instruments

Quality Certified Test Equipment Repair Services

When a piece of equipment fails you have the option to repair or replace that item. Oftentimes repair is an economical and efficient solution. Micro Precision’s repair offering provides advantages to our customers:

- Cost effective; often less than OEM

- Efficient; often much better turn-time than the OEM

- Flexibility; willingness to work with customers to meet their needs

- Warranted repairs

- Ability to service many obsolete instruments

Cost Effective Test Equipment Options

From the leasing of specialized electronic equipment for a specific task, to the purchase of physical and dimensional tools, we offer leasing services as well as used test equipment sales. We also locate hard-to-find electronics, and provide flexible options to meet ever-changing equipment needs.

Cost Effective Test Equipment Options

From the leasing of specialized electronic equipment for a specific task, to the purchase of physical and dimensional tools, we offer leasing services as well as used test equipment sales. We also locate hard-to-find electronics, and provide flexible options to meet ever-changing equipment needs.

Our Capabilities

Micro Precision can perform instrument calibration services on equipment from variety of applications for specific industries and lines of business. If you have a calibration need that is not listed in this area, please contact us.

Elektrisch

Micro Precision bietet akkreditierte elektrische Kalibrierungsdienste mit Multimetern, Multifunktionskalibratoren, Oszilloskopen und Stromversorgungsgeräten an.

Optical

Micro Precision ist ein akkreditiertes Kalibrierungslabor für Optik, Licht und Faseroptik.

Chemical

Micro Precision ist ein akkreditiertes thermodynamisches & chemisches Kalibrierungslabor für Temperatur, Feuchte, Biowissenschaften und Pharmazie.

RF - Microwave

Micro Precision akkreditiertes RF- & Mikrowellen-Kalibrierungslabor.

Mechanical & Dimensional

Das akkreditierte Labor für mechanische und dimensionelle Kalibrierung von Micro Precision bietet Dienstleistungen in den Bereichen Druck, Drehmoment, Kraft, Durchfluss, Geschwindigkeit und Traglast von Flugzeughebern.

Halbleiter

ANAB akkreditiert nach ISO/IEC 17025-2017 Akkreditierte Halbleiter-Waferdicke und Präzisionsstufenhöhenkalibrierung.

Calibration Needs. Simplified.

Full-Stack Prüfgeräte und Kalibrierungsdienste für Instrumente.

Weltweite Dienstleistungen

Providing technical and quality value added services, OEM support, and asset management solutions.