Zeiss Accura II CMM / Coordinate Measuring Machine – 900 mm X, 1600 mm Y, and 800 mm Z

Please use the request form to start a calibration services quote. You may also request equipment sales or repair services.

| Service & Purchase | Preise |

|---|---|

| Standard calibration to manufacturers specifications. | Inquire for pricing |

| Calibration including pre and post calibration data. | Inquire for pricing |

| Calibration with 17025 accreditation. | Inquire for pricing |

| Equipment repair to manufacturers specifications. | Inquire for pricing |

Beschreibung

The Zeiss Accura II CMM (Coordinate Measuring Machine) is a high-precision metrology system designed for accurate dimensional measurements, quality control, and inspection tasks in manufacturing and engineering environments. This advanced CMM combines cutting-edge technology, robust construction, and sophisticated measurement capabilities to meet the demands of precision engineering and quality assurance. Here are the key specifications of the Zeiss Accura II CMM:

- Measurement Range: Offers a generous measurement range of 900 mm in the X-axis, 1600 mm in the Y-axis, and 800 mm in the Z-axis, providing ample space for measuring large workpieces, components, and assemblies with complex geometries.

- Accuracy: Provides high measurement accuracy and repeatability, typically within micrometer or sub-micrometer tolerances, ensuring precise and reliable dimensional measurements for quality control and inspection purposes.

- Probe Options: Compatible with a range of touch-trigger probes, scanning probes, and non-contact measurement sensors, allowing for versatile measurement techniques such as point-to-point probing, scanning, surface profiling, and feature measurement.

- Multi-Sensor Capability: Supports multi-sensor configurations, enabling integration of optical sensors, laser scanners, vision systems, and tactile probes for comprehensive measurement capabilities and increased flexibility in measurement tasks.

- CAD Integration: Integrates seamlessly with CAD (Computer-Aided Design) software and metrology software platforms, allowing for CAD-based programming, model-based inspection, and automated measurement routines based on digital models and drawings.

- Software Features: Includes advanced metrology software with powerful analysis tools, reporting functionalities, GD&T (Geometric Dimensioning and Tolerancing) capabilities, statistical analysis, and automation features for efficient and accurate measurement workflows.

- Granite Construction: Built on a rigid granite base and precision mechanical components, providing stability, thermal stability, and vibration damping properties essential for accurate and repeatable measurements in challenging manufacturing environments.

- Motorized Axis: Equipped with motorized X, Y, and Z axes for programmable and automated movement, positioning, and measurement routines, enhancing measurement efficiency, repeatability, and throughput.

- Touchscreen Interface: Features an intuitive touchscreen interface for user-friendly operation, measurement setup, program execution, data visualization, and result interpretation, ensuring ease of use for operators.

- Environmental Control: Some models may offer environmental control features such as temperature compensation, air filtration, and humidity control to maintain measurement accuracy and stability in varying environmental conditions.

- Safety Features: Includes safety features such as collision detection, emergency stop, and interlocks to protect the machine, operators, and workpieces during measurement operations.

- Application: Suitable for dimensional inspection, geometric verification, reverse engineering, tool and mold inspection, part qualification, and metrology applications in industries such as automotive, aerospace, medical devices, electronics, and more.

- Calibration and Maintenance: Requires regular calibration, maintenance, and verification to ensure measurement accuracy, with calibration procedures, service intervals, and maintenance guidelines provided by the manufacturer for optimal performance and longevity.

In summary, the Zeiss Accura II CMM is a state-of-the-art coordinate measuring machine offering exceptional measurement capabilities, accuracy, versatility, and automation features for precise dimensional metrology and quality control in manufacturing and engineering industries.

Produktsuche

Laboratory Calibration

Micro Precision operates 36 laboratories globally providing reliable localized support

- Certified metrologists staffing laboratories in North America, Central America, South America, Europe, Asia, and the Middle East

- Comprehensive scopes of accreditation to meet a broad range of customer needs

- Expedited calibration services available

- Pickup and delivery services available

- Environmentally controlled facilities to ensure high quality and accurate calibrations and measurements.

Laboratory Calibration

Micro Precision operates 36 laboratories globally providing reliable localized support

- Certified metrologists staffing laboratories in North America, Central America, South America, Europe, Asia, and the Middle East

- Comprehensive scopes of accreditation to meet a broad range of customer needs

- Expedited calibration services available

- Pickup and delivery services available

- Environmentally controlled facilities to ensure high quality and accurate calibrations and measurements.

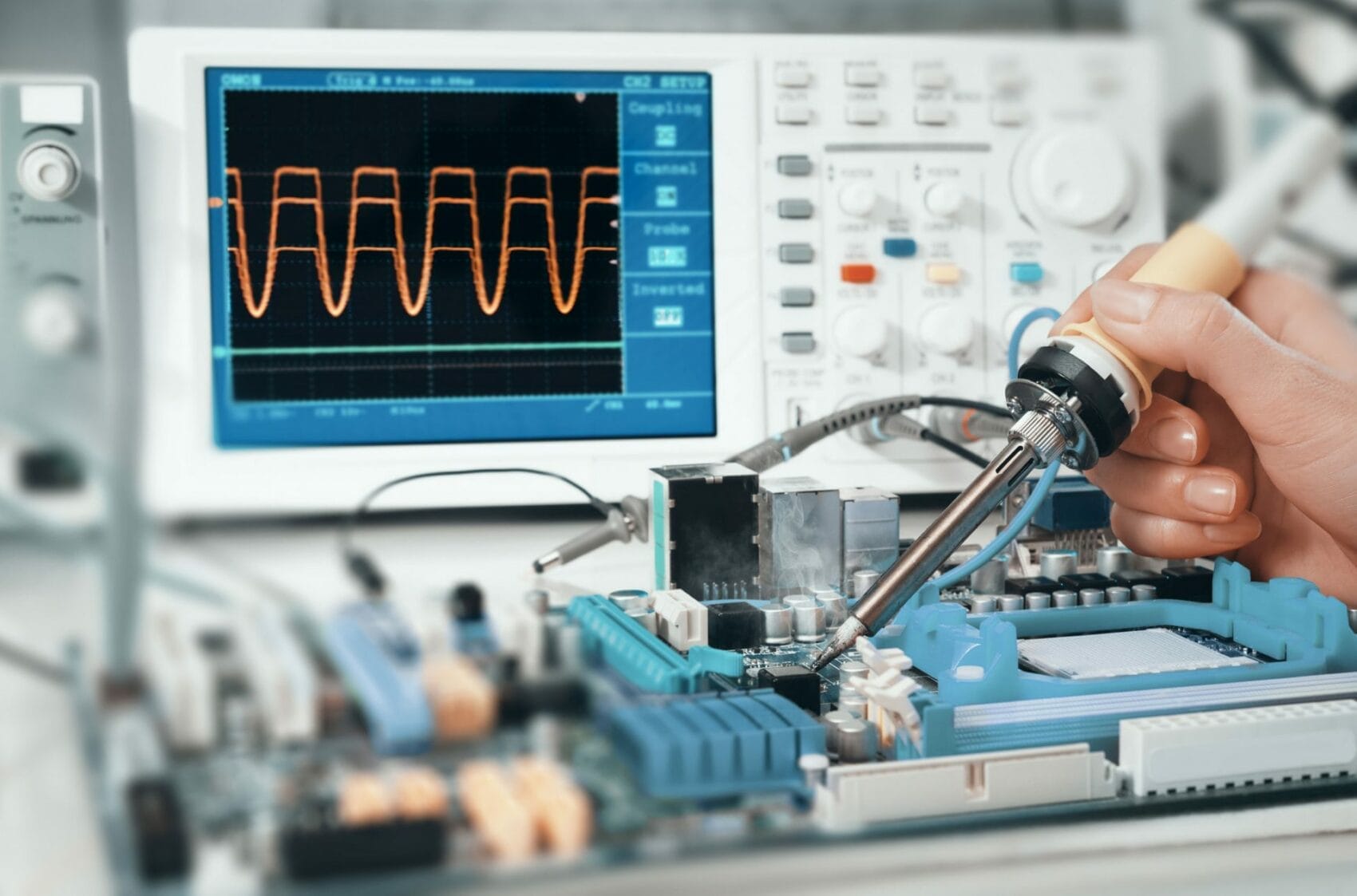

Quality Certified Test Equipment Repair Services

When a piece of equipment fails you have the option to repair or replace that item. Oftentimes repair is an economical and efficient solution. Micro Precision’s repair offering provides advantages to our customers:

- Cost effective; often less than OEM

- Efficient; often much better turn-time than the OEM

- Flexibility; willingness to work with customers to meet their needs

- Warranted repairs

- Ability to service many obsolete instruments

Quality Certified Test Equipment Repair Services

When a piece of equipment fails you have the option to repair or replace that item. Oftentimes repair is an economical and efficient solution. Micro Precision’s repair offering provides advantages to our customers:

- Cost effective; often less than OEM

- Efficient; often much better turn-time than the OEM

- Flexibility; willingness to work with customers to meet their needs

- Warranted repairs

- Ability to service many obsolete instruments

Cost Effective Test Equipment Options

From the leasing of specialized electronic equipment for a specific task, to the purchase of physical and dimensional tools, we offer leasing services as well as used test equipment sales. We also locate hard-to-find electronics, and provide flexible options to meet ever-changing equipment needs.

Cost Effective Test Equipment Options

From the leasing of specialized electronic equipment for a specific task, to the purchase of physical and dimensional tools, we offer leasing services as well as used test equipment sales. We also locate hard-to-find electronics, and provide flexible options to meet ever-changing equipment needs.

Our Capabilities

Micro Precision can perform instrument calibration services on equipment from variety of applications for specific industries and lines of business. If you have a calibration need that is not listed in this area, please contact us.

Elektrisch

Micro Precision bietet akkreditierte elektrische Kalibrierungsdienste mit Multimetern, Multifunktionskalibratoren, Oszilloskopen und Stromversorgungsgeräten an.

Optical

Micro Precision ist ein akkreditiertes Kalibrierungslabor für Optik, Licht und Faseroptik.

Chemical

Micro Precision ist ein akkreditiertes thermodynamisches & chemisches Kalibrierungslabor für Temperatur, Feuchte, Biowissenschaften und Pharmazie.

RF - Microwave

Micro Precision akkreditiertes RF- & Mikrowellen-Kalibrierungslabor.

Mechanical & Dimensional

Das akkreditierte Labor für mechanische und dimensionelle Kalibrierung von Micro Precision bietet Dienstleistungen in den Bereichen Druck, Drehmoment, Kraft, Durchfluss, Geschwindigkeit und Traglast von Flugzeughebern.

Halbleiter

ANAB akkreditiert nach ISO/IEC 17025-2017 Akkreditierte Halbleiter-Waferdicke und Präzisionsstufenhöhenkalibrierung.

Calibration Needs. Simplified.

Full-Stack Prüfgeräte und Kalibrierungsdienste für Instrumente.

Weltweite Dienstleistungen

Providing technical and quality value added services, OEM support, and asset management solutions.