Thriving in various environments, modern technology never fails to captivate us with its complexities. Among those contributing to its growth are accelerometers – an innovative invention that have revolutionized the industry with their versatile applications. By detecting acceleration, tilt, and motion, these sensors are used for a vast array of purposes, ranging from smartphones to aircrafts. With the intention of providing insight into the mechanics behind these ingenious devices, this article will explore their numerous applications and the significance of precise calibration.

What is an Accelerometer?

Accelerometers are built to gauge acceleration, i.e., the pace at which an object’s speed or direction varies. Such sensors usually have a spring-fixed weight that undulates counter to the acceleration in question. In other words, an accelerometer senses how fast the direction or swiftness of an object transforms.

The degree of acceleration is unveiled by the output, which is processed and amplified by a circuit, after the sensor detects movement and transforms it into an electrical signal.

What Does an Accelerometer Measure?

Accelerometers perform a variety of measurements pertaining to physical quantities. This includes:

- Linear acceleration: The measurement for acceleration in a straight line is expressed in meters per second squared. (m/s²).

- Angular acceleration: The measure of an object’s acceleration while rotating around an axis is expressed in radians per second squared. (rad/s²).

- Gravitational force: The measurement of the force of gravity on an object is expressed in newtons. (N).

Different Types of Accelerometers

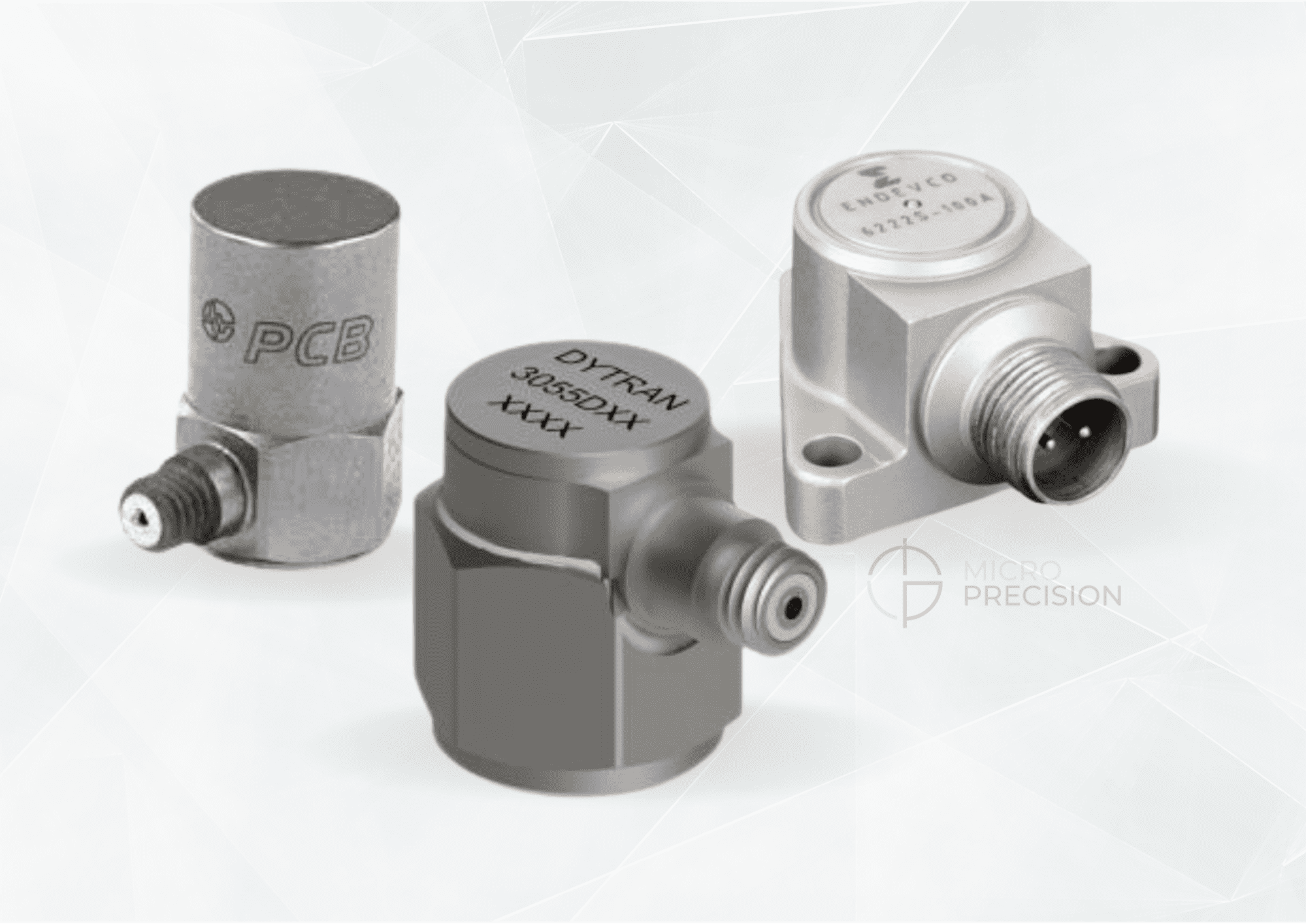

There are different types of accelerometers that use unique technologies to measure acceleration. The three main types are:

- Capacitive accelerometers: By utilizing the change in capacitance between two plates, these accelerometers are able to produce an electrical signal when subjected to acceleration. It’s worth noting that capacitance refers to the ability of two conductors to store an electrical charge.

- Piezoelectric accelerometers: These accelerometers utilize the piezoelectric effect to produce an electrical signal in response to acceleration. The piezoelectric effect is a property of specific materials that enables them to generate an electric charge under mechanical stress.

- MEMS (Micro-Electro-Mechanical Systems) accelerometers: The use of miniaturized sensors and electronics has enabled the creation of accelerometers that are highly compact. MEMS accelerometers, specifically, are exceptionally small and lightweight, rendering them perfect for wearable devices and other space-constrained applications.

Applications of Accelerometers

The versatile and useful nature of accelerometers is evident in the wide range of industries that make use of them. In the automotive industry, these devices are integral components of airbag deployment systems, accurately triggering airbags during significant deceleration caused by collisions. Consumer electronics benefit from accelerometers as well, enabling features like screen rotation and gesture recognition on smartphones. Reliable and accurate navigation, flight control, and pilot training are ensured in the aerospace industry thanks to accelerometers. In industrial settings, these devices monitor machinery, analyze vibrations, and optimize manufacturing processes. Sports and healthcare wearables also rely on accelerometers to track physical activity, aid recovery and prevent injuries.

How Often Should I Calibrate My Accelerometer?

Having professionals regularly calibrate accelerometers is crucial to ensure accurate measurements. The calibration frequency will vary depending on the specific application and environment in which the accelerometer is used.

To guarantee precision, some high-stakes applications, such as airbag deployment systems, may call for frequent calibrations, despite the yearly recommendation for accelerometer calibration.

In spite of this, an accelerometer’s necessary calibration frequency can be influenced by its operational surroundings. If used in demanding scenarios where vibrations or elevated temperatures exist, more frequent calibration may be mandatory than it would in a less taxing environment.

What Happens If I Don’t Calibrate My Accelerometers?

Regular accelerometer calibration is vital for ensuring precise measurements. Incorrect data interpretation due to failure to calibrate can be quite risky, particularly in hazardous situations. A collision could lead to an airbag system malfunction, putting lives in jeopardy due to poor calibration. Don’t play a risky game with inaccurate readings and always make sure to calibrate your accelerometers regularly.

Accelerometers are crucial sensors for various applications where accuracy plays a key role. Calibration knowledge and understanding of their functionality will ensure their reliability when in use. If you’re enthusiastic about discovering our calibration services for accelerometers, just ask for a free quote catering to your specific model.