Calibrating the backflow test gauge is crucial for assessing the functionality of backflow prevention devices and ensuring water safety. The most important part of this practice is calibrating backflow test gauges for water safety measures. This article emphasizes precision as a significant aspect of backflow test gauge calibration to safeguard against potential hazards.

What are Backflow Prevention Valves?

Understanding the purpose of backflow prevention valves is essential to grasp the significance of periodic testing. They act as gatekeepers, preventing the unwanted contamination of public drinking water by wastewater from commercial buildings. The backflow test gauge is a necessary tool used for inspection to check if prevention devices are working effectively.

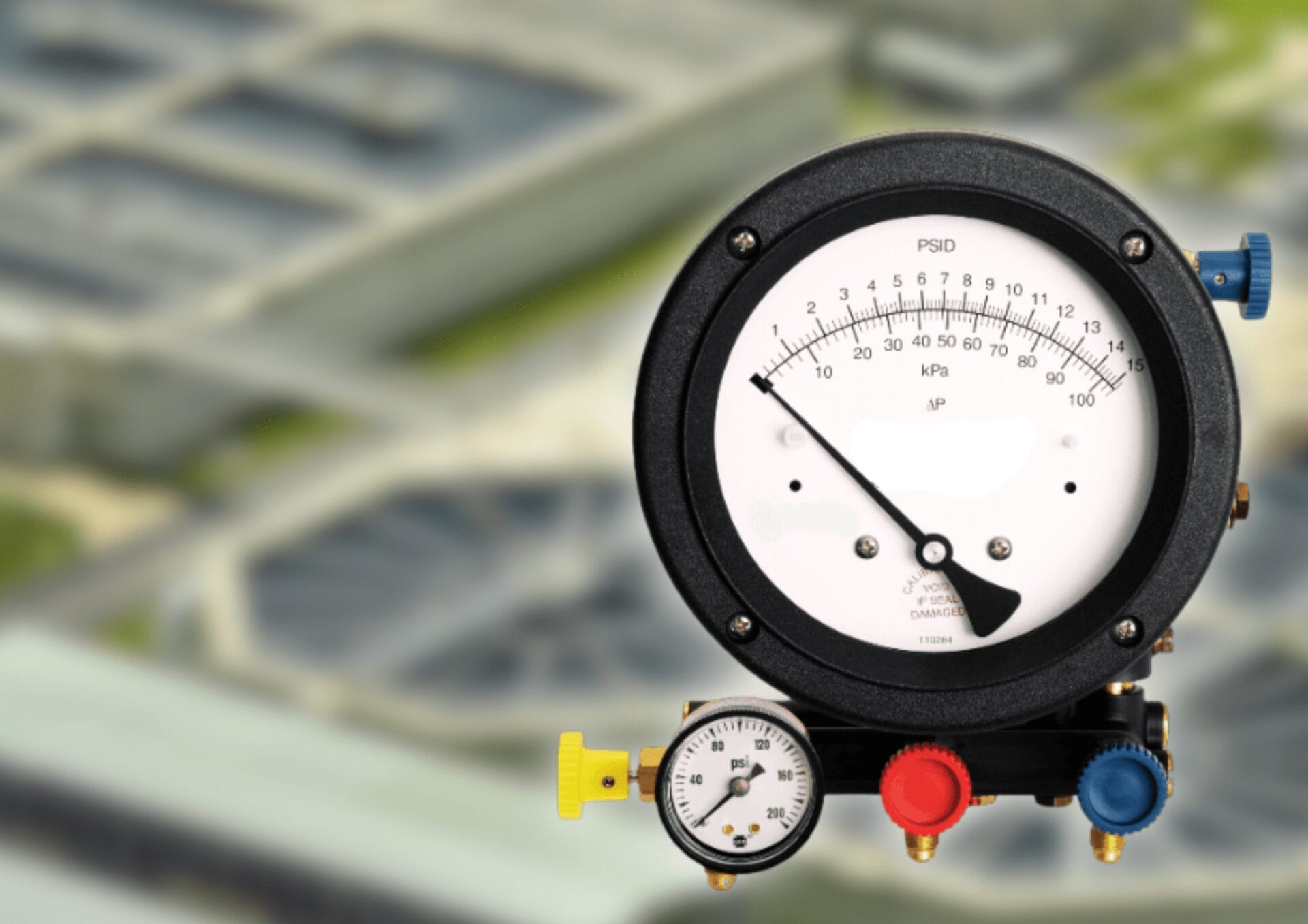

A nuanced approach to calibration is vital due to the varying components of the test kits – including fittings, needle valves, hoses, a case, and a differential pressure gauge – which exhibit diversity depending on the model, type, and brand utilized.

The backflow test kit/gauge plays a valuable role in determining the efficacy of backflow prevention valves. The kit’s differential pressure readings provide insight into valve functionality. A standard backflow test usually takes 20 to 30 minutes but may be extended for repairs.

Backflow Test Gauge (Kit) Calibration

At the center of backflow test gauge accuracy is calibration. Making sure the kit measures up to a standard is key. Its ultimate goal is to affirm the kit can properly test backflow prevention valves. Accurate and trustworthy results rest on this precise alignment.

To maintain water safety standards, EPA regulations require an annual inspection and certification of backflow test gauges. A thorough examination of all components is ensured by simulating a backflow test during the inspection to identify any issues. This is a vital process to ensure the proper functionality of the gauges.

When is Backflow Test Gauge Calibration Needed?

When readings are off, you need to calibrate them regularly. This should be part of your regular maintenance plan to keep the accuracy and quality of your results. It is important to note that routine inspection and calibration of your backflow test gauge should be done by a certified calibration provider, like Micro Precision.

Post-calibration and Repair

Frequent use can lead to wear and damage to components, even after careful calibration. It’s critical to identify post-calibration problems, and we provide thorough backflow gauge repairs. The continuous operation of your equipment is our top priority, which is why inspecting it on a regular basis is highly recommended.

Micro Precision Calibration

We at Micro Precision Calibration have decades of experience. We place a strong emphasis on calibration since we know that accurate measurements are essential to conducting successful backflow tests. We guarantee that our clients obtain accurate and dependable calibration services since we are dedicated to perfection. Here are some of the calibration types of

- Traceable

- Traceable with Data

- Accredited Calibration (ISO:IEC 17025:2024, Z540.3)

Ensure quality backflow gauge calibration at Micro Precision. Inquire now to learn more and get a free quote.