Accurate test equipment is essential in many industries for ensuring accurate measurements and quality control. Deciding whether calibration or repair is the best course of action when maintenance is required can be challenging. Accurate instrument repair is needed for fixing faulty components, while calibration services are essential for achieving accuracy. In order to help you decide which one should be done to your test equipment, this article helps clarify the distinctions between equipment calibration and repair.

Understanding Calibration

The process of calibration includes adjusting test equipment to ensure it is giving accurate results. It involves assessing the readings from the equipment and comparing it to the known standard, if it does not meet it then adjustment is necessary. Reputable businesses like Micro Precision offer equipment calibration services, which are essential for maintaining accuracy and dependability. Calibration service providers have trained professionals that have experience calibrating a variety of equipment, helping businesses meet the industry standard and requirements.

Looking into Repair

Accurate instrument repair is necessary to restore functionality when test equipment malfunctions. Inaccurate measurements and erroneous testing procedures can result from malfunctions, which can affect output and standard of work. Expert instrument repair technicians specialize in identifying and replacing broken parts to restore the equipment’s optimal performance. A reputable company in the field, Micro Precision offers dependable test equipment repair services and complete solutions to a range of problems.

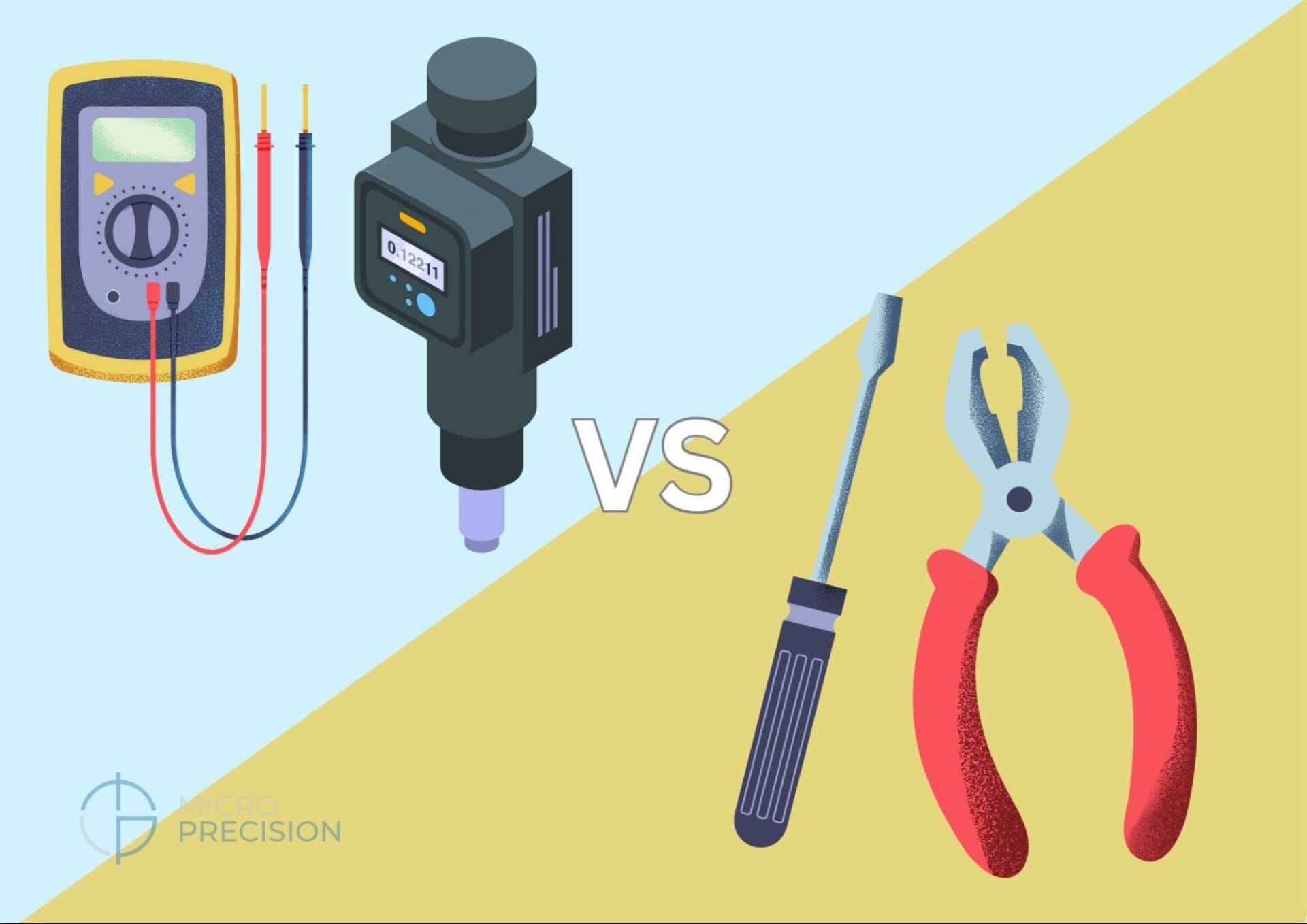

Calibration vs Repair: What are the Differences?

In order to improve accuracy and reliability, calibration focuses on adjusting the equipment’s measurements to match a recognized standard. Repair, on the other hand, focuses mainly on replacing damaged parts and restoring functionality. While repair seeks to address the underlying cause of the issue and aims to remove any inaccuracies, calibration ensures accurate readings.

Factors to Consider

There are a number of considerations when choosing between calibration and repair. First and foremost, the equipment’s condition and age are important. Calibration may be sufficient if the equipment is in good condition and is relatively new. Repair may be required, though, if it is older or has recurrent issues. Second, cost-effectiveness needs to be taken into account. While calibration services are typically less expensive, more complicated repairs might cost more. The impact on productivity and equipment downtime must also be assessed. When compared to repair, calibration frequently takes less time, reducing the amount of time the equipment is out of commission.

Working with Experts

Collaborate with professionals to make an informed decision and guarantee the best results for your test equipment. Equipment calibration services are provided by calibration services companies that have qualified technicians such as Micro Precision. Their expertise and cutting-edge facilities ensure precise adjustments are made to your specific instruments. Similarly, their instrument repair services include thorough analysis and practical solutions to get your equipment working in excellent condition again.

Long-Term Maintenance Strategies

Beyond choosing between immediate calibration and repair, it’s a great advantage to implement long-term maintenance strategies. The need for extensive repairs or frequent calibration is reduced by regular maintenance, which includes preventive measures. The lifespan and functionality of your test equipment will be maximized by setting up a maintenance schedule, keeping track of the work done, and following recommended maintenance practices.

Making the Right Decision

In summary, deciding between calibration and repair depends on a number of variables, such as the state of the equipment, cost-effectiveness, and impact on downtime. Accurate adjustments, as well as effective resolutions, are ensured by seeking professional advice from reputable calibration service providers and instrument repair specialists. You can optimize the precision, reliability, and durability of your test equipment by making an informed choice and putting long-term maintenance plans in place.

If you’re looking into having your equipment repaired or calibrated, get a trusted service provider like Micro Precision. Contact us or request a quote to get started.