Calibration or Repair: What's Right for Your Test Equipment?

Accurate test equipment is essential in many industries for ensuring accurate measurements and quality control. Deciding whether calibration or repair is the best course of action when maintenance is required can be challenging. Accurate instrument repair is needed for fixing faulty components, while calibration services are essential for achieving accuracy. In order to help you decide which one should be done to your test equipment, this article helps clarify the distinctions between equipment calibration and repair.

Understanding Calibration

The process of calibration includes adjusting test equipment to ensure it is giving accurate results. It involves assessing the readings from the equipment and comparing it to the known standard, if it does not meet it then adjustment is necessary. Reputable businesses like Micro Precision offer equipment calibration services, which are essential for maintaining accuracy and dependability. Calibration service providers have trained professionals that have experience calibrating a variety of equipment, helping businesses meet the industry standard and requirements.

Looking into Repair

Accurate instrument repair is necessary to restore functionality when test equipment malfunctions. Inaccurate measurements and erroneous testing procedures can result from malfunctions, which can affect output and standard of work. Expert instrument repair technicians specialize in identifying and replacing broken parts to restore the equipment's optimal performance. A reputable company in the field, Micro Precision offers dependable test equipment repair services and complete solutions to a range of problems.

Calibration vs Repair: What are the Differences?

In order to improve accuracy and reliability, calibration focuses on adjusting the equipment's measurements to match a recognized standard. Repair, on the other hand, focuses mainly on replacing damaged parts and restoring functionality. While repair seeks to address the underlying cause of the issue and aims to remove any inaccuracies, calibration ensures accurate readings.

Factors to Consider

There are a number of considerations when choosing between calibration and repair. First and foremost, the equipment's condition and age are important. Calibration may be sufficient if the equipment is in good condition and is relatively new. Repair may be required, though, if it is older or has recurrent issues. Second, cost-effectiveness needs to be taken into account. While calibration services are typically less expensive, more complicated repairs might cost more. The impact on productivity and equipment downtime must also be assessed. When compared to repair, calibration frequently takes less time, reducing the amount of time the equipment is out of commission.

Working with Experts

Collaborate with professionals to make an informed decision and guarantee the best results for your test equipment. Equipment calibration services are provided by calibration services companies that have qualified technicians such as Micro Precision. Their expertise and cutting-edge facilities ensure precise adjustments are made to your specific instruments. Similarly, their instrument repair services include thorough analysis and practical solutions to get your equipment working in excellent condition again.

Long-Term Maintenance Strategies

Beyond choosing between immediate calibration and repair, it's a great advantage to implement long-term maintenance strategies. The need for extensive repairs or frequent calibration is reduced by regular maintenance, which includes preventive measures. The lifespan and functionality of your test equipment will be maximized by setting up a maintenance schedule, keeping track of the work done, and following recommended maintenance practices.

Making the Right Decision

In summary, deciding between calibration and repair depends on a number of variables, such as the state of the equipment, cost-effectiveness, and impact on downtime. Accurate adjustments, as well as effective resolutions, are ensured by seeking professional advice from reputable calibration service providers and instrument repair specialists. You can optimize the precision, reliability, and durability of your test equipment by making an informed choice and putting long-term maintenance plans in place.

If you're looking into having your equipment repaired or calibrated, get a trusted service provider like Micro Precision. Contact us or request a quote to get started.

Unlocking Network Potential: Exploring the Versatility of the DSX 5000 Fluke Tester

Network performance is essential for seamless operations and effective communication in today's fast-paced digital environment. Employing advanced and powerful tools that can optimize performance is necessary if networks are to reach their full potential. The DSX 5000 Fluke Tester, a versatile and advanced cable analyzer, is a great example of such tool. This article explores how the DSX Fluke Cable Analyzer can maximize network efficiency and realize its full potential by delving into its features and capabilities.

Understanding the DSX 5000 Fluke Tester

A cutting-edge cable analyzer made to meet the demands of modern networks is the DSX 5000 Fluke Tester. The accuracy, speed, and adaptability of this device offer optimal network performance. Its versatility includes its application in different types of industrial settings because it supports various network types and protocols.

Comprehensive Cable Analysis

The Fluke DSX-5000 excels in cable analysis, offering precise and detailed testing and certification. With this, network administrators can identify faults, ensure proper installation, and optimize transmission speed. The DSX 5000 provides unmatched precision, resulting in high-performing reliable networks, whether it identifying a faulty connector or detecting improper cable lengths.

Advanced Network Diagnosis

A vital role in locating and fixing performance problems is network diagnosis. The Fluke DSX 5000 offers advanced diagnostic capabilities, not just basic testing. Administrators can identify the underlying causes of network issues by using its ability to detect signal degradation, cross-talk, and interference. With this information, they can quickly address problems and improve network performance, resulting in smooth operations and reduced amount of downtime.

Streamlining Network Optimization

Performance optimization through effective network optimization is critical This process is made easier by the DSX 5000 Fluke Analyzer, which offers insightful information on network speed and performance. Administrators can identify areas for improvement and implement targeted optimizations with the ability to measure latency, bandwidth, and throughput.

Future-Proofing and Ensuring Compliance

Network integrity and security must be maintained by adhering to industry standards and regulations. By validating network performance against industry benchmarks, the Fluke DSX-5000 Analyzer aids in ensuring compliance. Additionally, it is essential for future-proofing networks because it gives administrators the ability to confirm performance for advances in technology and higher data rates. Organizations can confidently navigate the constantly changing landscape of networking requirements with the help of the Fluke DSX Cable Analyzer.

Unlocking network potential and increasing effectiveness are both possible with the DSX 5000 Fluke Tester, a potent tool. Because of its many functionalities, including thorough cable analysis, cutting-edge network diagnostics, and efficient network optimization, it is a vital tool for network administrators. Organizations can achieve optimal network performance, ensuring seamless operations and increased productivity, by utilizing the capabilities of the DSX 5000 Fluke Tester.

Fluke DSX-5000 FAQs:

1. What makes the DSX-5000 Fluke Tester different compared to other cable analyzers on the market?

This equipment stands out compared with other testers in the market because of its advanced features. It is versatile and has unparalleled accuracy and speed. It provides a holistic solution for boosting network performance using its comprehensive cable analysis, streamlined network optimization, and advanced network diagnostics.

2. Are there certifications or training required before you operate the DSX 5000?

Operating the DSX 5000 Fluke Tester requires experience, it is highly recommended to undergo training even though certifications is not mandatory. The DSX 5000 Fluke Tester's manufacturer, Fluke Networks, provides training programs and certifications that can improve your knowledge of the equipment and functions. A thorough training program guarantees accurate interpretation of the test results and the best possible use of the tester's skills.

3. Does the DSX 5000 Fluke Tester support automated testing and batch processing?

Yes, automated testing and batch processing are supported by the DSX 5000 Fluke Tester, greatly enhancing productivity and efficiency. Users can use it to automate repetitive tasks, create test profiles and run simultaneous tests on several cable runs. The software interface of the tester makes it simple to configure and run automated tests, saving valuable time and effort.

4. Can the DSX 5000 Cable Analyzer be integrated with other network management software or tools?

Yes, other network management tools and software can be integrated with the Fluke DSX-5000 Tester. It enables seamless integration into existing network infrastructure and offers compatibility with a range of network management platforms.

If you're in need of any Fluke DSX 5000 calibration, repair, sale, or lease services, don't hesitate to reach out to us or simply request a quote.

Oscilloscope 101: A Beginner's Guide to Using and Understanding Oscilloscopes

Oscilloscopes are essential tools for engineers and enthusiasts working in the fields of electronics and electrical engineering because they allow for accurate waveform measurements and analysis. This article will cover the fundamentals of oscilloscopes and introduce you to their applications, usage, and features.

What is an Oscilloscope?

An oscilloscope is a type of electronic test equipment used to observe and measure electrical signal waveforms. It helps with observing how voltage signals change over time, enabling the user to analyze amplitude, timing, and frequency. Additionally, engineers can detect abnormalities and diagnose errors in electronic circuits by using this instrument. A display screen, vertical and horizontal controls, input connectors, and triggering mechanisms are some of its essential components. Some of the industries that use an oscilloscope are electronics, engineering, and telecommunications.

What Can You Measure with an Oscilloscope?

Various signal parameters can be precisely measured with an oscilloscope. Engineers can get assess the amplitude characteristics of a waveform using voltage measurements such as peak-to-peak, amplitude, and root mean square (RMS). Period, frequency, and rise/fall time are examples of frequency and time measures that can be used to understand the periodicity and timing aspects of a signal. Moreover, if you buy a used or new oscilloscope, it has the capacity to provide advanced measuring features including Fast Fourier Transform (FFT) for frequency domain analysis and math functions for mathematical operations on waveforms, allowing the study of phase connections between various waveforms.

Practical Application of Oscilloscopes

Because of their versatility, oscilloscopes are considered indispensable across a wide range of applications. They are used by engineers to test and troubleshoot electronic circuits with noise interface or signal integrity. They are also useful for analyzing audio signals to ensure proper data transmission and reception, testing the performance of power electronics and motor drives, and analyzing audio signals and waveforms.

How to Read an Oscilloscope

Interpreting waveforms and other elements shown on an oscilloscope is a fundamental skill. In order to do so, it requires understanding its parts. The display is the screen that shows the waveforms measures, the horizontal axis determines time and the vertical axis represents voltage. The timebase setting determines how much time each horizontal division on the screen represents. The waveform's vertical scaling is controlled by the voltage settings. To stabilize the waveform display, triggering is crucial. The waveform’s shape can appear triangular, square or sine, these indicate what type of signal is being measured. While the period represents the amount of time it takes for a waveform to complete one cycle, the amplitude denotes the voltage level.

Oscilloscopes are able to measure voltage and time. The amplitude, which is half of the peak-to-peak voltage, the peak-to-peak voltage, and the RMS (root mean square) voltage can all be measured. Here are examples of time measurements:

- Period - the amount of time it takes for a cycle to complete

- Frequency - the number of cycles per second

- Rise/fall time - the amount of time it takes for a signal to change between two distinct voltage levels.

By understanding these concepts and knowing what controls and settings to adjust, you can effectively read waveforms shown on the screen, enabling you to get insights and interpretations from the data gathered.

Oscilloscopes are powerful tools for analyzing, measuring, and interpreting electronic waveforms. Having a good foundation when it comes to understanding the instrument opens up many possibilities in signal analysis and troubleshooting.

Once you have the basic understanding, it is recommended to expand your knowledge. Seek out more training, research materials, forums, and tutorials in order to provide more in-depth explanations and utilize their practical applications.

Continuously learning and applying what the oscilloscope can do will make you more confident in analyzing waveforms, troubleshooting circuits, and making informed design decisions. Hands-on experimentation and practice is also a great impact when it comes to mastering the device. The oscilloscope is a powerful instrument, and the more you become engaged with its functions, the more proficient you become.

If you are currently exploring oscilloscope captions to buy contact us or request a quote.

Maximizing Your Measurements: A Comprehensive Look at the Tektronix 2467B Oscilloscope

An oscilloscope is one of the essential tools used by electronics engineers who analyze electronic signals. One of the many reliable oscilloscopes is the Tektronix 2467B, a graph-display tool that plots an electrical signal as a graph. This device stands out because of its reliability, versatility, and other advanced capabilities. This article comprehensively overviews the Tektronix 2467B oscilloscope, including its features and specs, applications, techniques, applications, maintenance and FAQs.

Tektronix 2467B Oscilloscope Specifications and Features

The Tektronix 2467B oscilloscope is a powerful tool that has been used and is still continuously being used in many fields. With its four channels and voltage sensitivity range, multiple signals can be measured simultaneously and slight signal changes can easily be detected. This oscilloscope comes with advanced trigger options and capabilities, which provide a comprehensive analysis of the signals. Sharing and storing measurement results is easy because of the device's interfaces and storage options. Overall, the specs make this oscilloscope a reliable and versatile tool.

Here is the list of Tektronix 2467B oscilloscope's specs:

- Bandwidth: 400 MHz

- Channels: 4

- Sample Rate: 1 GS/s

- Record Length: 7,000 points per channel

- Vertical Resolution: 8 bits

- Rise Time: 0.875 ns

- Cursors: Time and Voltage

- Measurement Capabilities: Voltage, Frequency, Period, Pulse Width, Rise/Fall Time, Duty Cycle, and more

- Sensitivity: 2 mV/div to 10 V/div

- Input Impedance: 1 MΩ // 20 pF

- Maximum Input Voltage: 400 Vrms

- Display: Monochrome CRT with 8x10 division graticule

- Built-in storage: 3.5-inch floppy disk drive

- Interfaces: RS-232, GPIB, and Centronics Printer Port

- Dimensions: 16.7” x 6.1” x 19.4”

- Weight: 13.5 kg

How to Use the Tektronix 2467B Oscilloscope

Using the Tektronix 2467B oscilloscope is a breeze, but there are essential steps to follow to get reliable and accurate measurements. First, make sure to set up the device and connect the probes properly. Then, adjust the horizontal and vertical controls to display the waveform you are interested in. With this device, you can measure voltage, period, and frequency and analyze waveforms using features like peak-to-peak and RMS measurements. Also, you can use cursors, markers, and other measurements to compute factors like rise time, fall time, and pulse width.

Advanced Techniques with the Tektronix 2467B Oscilloscope

Engineers can utilize techniques for more advanced applications such as FFT analysis, advanced triggering options, waveform averaging, persistence mode, and XY mode to maximize the capabilities of the Tektronix 2467B oscilloscope. With FFT analysis, you can determine a signal's harmonics, spectral properties, and frequency content. Advanced triggering settings help you isolate specific events or signal patterns and trigger the oscilloscope to capture them. Persistence mode and waveform averaging can assist with signal stability and noise reduction. Engineers can visualize phase differences or other correlations between signals using the XY mode, which allows them to display one channel's signal against the other.

Applications of the Tektronix 2467B Oscilloscope

The Tektronix 2467B oscilloscope is applicable in a wide range of industries such as telecommunications, aerospace, medical, automotive and so much more.

- In telecommunications, for example, engineers use the device to measure signals from communications systems and diagnose problems related to interference, noise, and distortion.

- In aerospace, the oscilloscope helps analyze signals used for the aircraft systems' navigation, communication, and controls.

- In the medical field, the tool helps engineers test and validate medical devices such as pacemakers, ultrasound machines, and medical imaging equipment.

- In the automotive business, engineers use the oscilloscope to analyze the performance of electronic control units in vehicles and diagnose engine or transmission system issues.

Overall, the Tektronix 24678 oscilloscope is a flexible and dependable piece of equipment that can assist engineers working in various industries and give them reliable and accurate measurements.

Upgrading and Maintaining Tips

To keep the Tektronix 2467B oscilloscope functioning well, there are a few maintenance tips to follow. Users can upgrade the firmware and software regularly to access new features and bug fixes. Calibration by a professional is important periodically to ensure that the measurements remain accurate. Regular cleaning of the screen, case, and probes is necessary to avoid the buildup of dust and debris. The device's batteries can also be replaced when they are low or have lost their capacity. Lastly, it's important to store the oscilloscope in a dry and cool place to prevent damage from heat, humidity, or sunlight.

Frequently Asked Questions

Where can I purchase a Tektronix 2467B oscilloscope?

This oscilloscope is already phased out by Tektronix. However, used or refurbished units are still being sold in the market. It is important to carefully research if the seller is trusted. You may contact us and inquire about its availability.

How can I troubleshoot common issues?

If your Tektronix 2467B oscilloscope is experiencing issues, refer to the user manual for tips and solutions. Common issues include problems with connectivity, display, and measurements. You may also contact the manufacturer of a certified service provider for further assistance if necessary.

How can I calibrate my Tektronix 2467B oscilloscope?

Regular calibration is essential to ensure that your device provides accurate measurements. However, calibration is a task that should only be performed by someone who is trained and certified to do so. Better leave it to the experts to make sure calibration is precise.

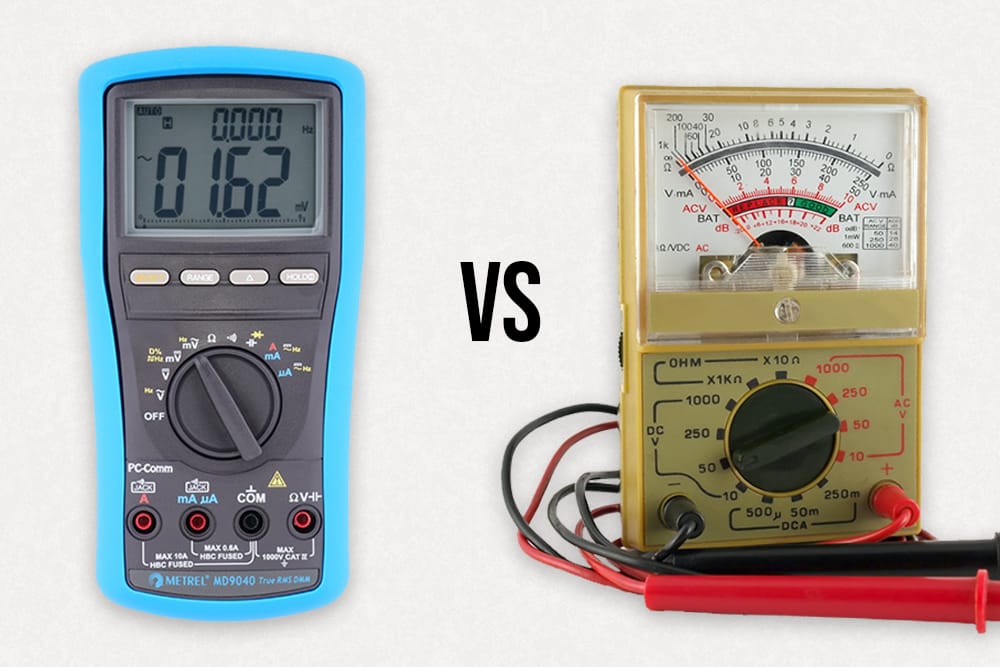

Digital vs. Analog Multimeters - Which Will Measure Up to Your Needs?

The proper equipment is essential while performing electric work. An effective tool for measuring voltage, current, resistance, and other electrical quantities is a multimeter. However, there are two different kinds of multimeter in the market: digital and analog. We'll explore the distinctions between these two multimeters in this article and see which one is the best that will meet your needs.

Digital Multimeter

Digital multimeter, also known as DMM, is the modern and digital equivalent of the analog multimeter. Beyond the standard voltage, current, and resistance measurements of an analog version, they use a microprocessor to measure and show values digitally with its LED or LCD screen.

One of the main advantages of digital multimeters is accuracy. They can measure values to multiple decimal points and are typically more accurate than an analog multimeter. They are ideal for operations like computer and electronics repair because they require precision.

There are certain features of a digital multimeter that also provide convenience. In general, they are designed to be portable and easy to carry due to their pocket-sized appearance. They also generate measurement results faster because of its technology and they require less frequency in calibration compared to an analog version.

The simplicity of using a digital multimeter is another benefit. They often have advanced features like data logging and auto-ranging, which make taking measurements easier and more effective.

Analog Multimeters

Analog multimeters, on the other hand, are the conventional analog version of multimeters. They measure using a moving pointer and display results on a printed scale. In comparison to digital multimeters, they are less complicated and more affordable, making them a great option for beginners and people on a tight budget.

These types of multimeters do offer certain benefits over digital ones. They are great for fieldwork since they are typically more robust and can survive harsh environments. They also don't require batteries to work, which means it is convenient to use anywhere and anytime.

However, analog multimeters also have some serious drawbacks. The accuracy issue is among its main disadvantages. They can only measure a limited number of significant digits and are less accurate than digital meters. This can be a significant issue for professional work or exact measurements when precision is essential.

Analog vs Digital Multimeter Accuracy

One of the most important factors to take into account when choosing a multimeter is its accuracy. Due to parallax errors, where the angle at which the user sees the reading might result in mistakes, analog multimeters are not as accurate as the digital one. In contrast, digital multimeters can measure reading with better precision and are less prone to parallax errors.

Analog multimeters can also drift over time, which can lead to errors. When the pointer's calibration is lost, there is drift, which can cause false readings. However, digital ones are simple to adjust, assuring accuracy over time.

Which Multimeter is Right for You?

The best multimeter for the job will rely on several factors, including budget, level of expertise and the nature of the task you'll be conducting. An analog multimeter can be the ideal option if you're new to electric work or on a limited budget. Aside from that they are less complicated and are more dependable to operate since they operate without batteries.

However, a better choice would be a digital multimeter. They present more accurate measurements. They are ideal for operations that highly require exact measurements. A clear reading is better at preventing further issues too.

But again, price should be taken into account. Generally, digital multimeters cost more than an analog, but they come with more advanced features and better precision. An analog multimeter can be the best option if the budget is limited.

It is important to consider personal preferences, experience level and purpose of usage when deciding which multimeter to buy. The ideal option could be an analog if you're comfortable using analog technology. On the other hand, a digital multimeter is perhaps the better option if you prefer a device with modern technology and better accuracy.

If you’re looking for multimeters or searching for a repair and calibration service for your device, you may request from us a quote or contact us for further inquiries.

How Often Should Your Equipment be Calibrated?

Calibrating equipment, in whatever field it may be, is crucial in ensuring that measurement instruments are accurate and reliable. The process involves adjusting and testing equipment to meet the required standard.

Importance of Calibration

Businesses must maintain the quality and safety of their products by ensuring that the equipment used provides accurate and reliable measurements. Inaccurate results may lead to costly errors, product defects, or health hazards.

Aside from that, the process of calibration helps to identify faults before they can result in significant issues. Regularly doing this can identify problems such as minor and major damages, wear and tear, and drift.

To maintain working equipment that always performs with accuracy, frequent calibration from an accredited calibration service provider is necessary. But the question is, how often should it be done?

How Frequent Should Equipment Be Calibrated

There is no one answer to how often calibration should be. Several factors should be taken into consideration. These include manufacturer's recommendations, frequency of use, operating equipment, industry regulations, and periodical calibration.

1. Manufacturer's recommendations

Guidelines are provided by manufacturers on how often instruments should be calibrated. The recommendations are based on the equipment's expected lifespan, environment it operates in, and its complexity. These are usually included in the equipment manual, and are highly recommended to be followed to maintain the accuracy and quality of the equipment.

2. Frequency of use

Another big factor is how frequent the equipment is used. Overtime, an instrument experienced wear and tear, leading to inaccurate measurements. The frequency of use, therefore, also determines how often an equipment should be calibrated. If it is continuously used for an extended period of time, it is recommended to calibrate more often than usual.

3. Operating environment

Operating environment contributes when deciding how often a calibration service should be done. Some fields use equipment in harsh environments that have extreme temperatures or high humidity, this will require more maintenance including calibration to ensure that the measurements are still accurate.

Another example is equipment used in dusty or dirty areas, they may require frequent calibration too. Debris accumulate overtime and they affect the instrument's accuracy.

4. Industry regulations

Some Industries have regulatory bodies that mandate the frequency of equipment calibration. For instance, the medical sector demands that particular devices, such blood pressure monitors and ECG equipment, be calibrated on a regular basis to assure correct data.

5. Periodical

Periodical calibration refers to the routine set at fixed intervals. It is a proactive initiative done to ensure that the equipment is functioning correctly and accurately. This is also a good approach because it helps prevent problems. Periodical calibration could be monthly, quarterly, annually or semi-annually, but other factors still play into the decision making of setting the timeline.

Immediate Calibration

Immediate Calibration

Despite the factors listed above about how to identify when to calibrate equipment. There are still instances that require urgent calibration. Here are some of those situations:

1. Equipment failure

In order to prevent additional damage and to assure accurate and dependable readings, it is crucial to calibrate the equipment as soon as it fails or exhibits symptoms of malfunction.

2. Out-of-tolerance readings

Immediate calibration is required to restore accuracy once readings produced are out of the tolerance range.

3. New Equipment

It is crucial to calibrate any new equipment that is installed or introduced into the workplace right once to make sure it is operating properly and providing precise readings.

4. Changes in environment

This refers to the changes in temperature, humidity, or pressure. All of these can impact the function of the equipment.

5. Safety Concerns

It is crucial to calibrate equipment often and immediately if it exhibits symptoms of failure since erroneous measurements might have detrimental effects on safety-critical applications, such as those in the healthcare or aerospace sectors.

In conclusion, equipment calibration is a crucial step in ensuring the precision and dependability of measuring devices. Deciding on its frequency is based on many factors such as recommendation of manufacturer, usage, working environment, industry regulations and if there's a preferred periodical schedule. However, take into consideration too if the equipment is in need of an immediate calibration.

A calibration service provider's expertise is essential in making sure that equipment is operating within the required accuracy range and minimizing the possibility of mistakes and false readings. Numerous advantages result from routine calibration, including increased measurement accuracy and dependability, longer equipment life, lower costs and downtime, and compliance with industry standards and regulations. Organizations may make sure that their equipment is precise and dependable by adopting and following a calibration program, which will boost production, profitability, and safety.

For years, Micro Precision has been considered as one of the experts in the calibration industry. If you need a dependable calibration service provider, you can inquire or request a quotation.

Measuring Up: Assessing the Agilent 34401A's Continued Relevance in the Industry

For 20 years, the Agilent 34401A multimeter has been a mainstay in the industry of electronics. It's known for its accuracy, dependability and ease of use, that's why it continues to be well-liked among professionals and enthusiasts despite newer multimeters being introduced in the market. In this article, we will evaluate the specifications, accuracy, applications and availability of the Agilent 34401a digital multimeter.

What is the Agilent 34401A?

This device is a digital benchtop multimeter designed with great accuracy and resolution for measuring voltage, current and resistance. It has a large, easy-to-read display, has simple controls and has a number of measurement modes, including resistance, continuity, DC voltage, AC voltage, DC current and AC current. Additionally, it is capable of measuring diode voltage, frequency and period.

Agilent 34401a specs

One of the device’s standout qualities is its accuracy, which is frequently mentioned as a major factor in why it still holds value in the modern market. A voltage range of up to 1000V DC and 750V AC, a current range of up to 3A DC and AC, and a resistance range of up to 100MΩ are all features of the Agilent 34401A multimeter. One of the most accurate multimeters on the market, it offers an accuracy of up to 0.0035% and a resolution of up to 6.5 digits. Furthermore, the Agilent 34401A supports high-speed measurements in time-sensitive applications thanks to its sample rate of up to 1000 readings per second.

List of Specifications:

- Voltage measurement range: 100 mV to 1000 V DC, 100 mV to 750 V AC

- Current measurement range: 100 µA to 3 A DC, 100 µA to 3 A AC

- Resistance measurement range: 100 Ω to 100 MΩ

- Resolution: up to 6.5 digits

- Accuracy: up to 0.0035%

- Frequency measurement range: 300 Hz to 1 MHz

- Sample rate: up to 1000 readings per second

- Display: 2-line, 16-character alphanumeric

- Dimensions: 88.1 mm x 214.2 mm x 297.2 mm (3.47 in x 8.43 in x 11.7 in)

- Weight: 2.2 kg (4.9 lbs)

Applications of the Agilent Multimeter

Electronics, automotive, and aerospace are just a few of the businesses and disciplines that often use the Agilent 34401A multimeter. It is a tool used in the electronics industry for testing and debugging electrical circuits, parts, and systems. On the other hand, in the automotive industry, it is used for measuring the current, voltage, and resistance of batteries, alternators, and sensors. While in the aerospace field, the Agilent 34401A is used to test and validate the functionality of avionics systems and components.

Where to get the Agilent 34401a

Although Keysight Technologies, formerly known as Agilent, is no longer producing the Agilent 24401A model, it is still widely available in the used and refurbished market. There are still companies, like Micro Precision, offering rental, repair and calibration for this device. There are still several suppliers with warranty and calibration certificates, ensuring the instrument's complete functionality and accuracy. Prices for the tool vary depending on the instrument's features and condition, but they are often less expensive than the models released in recent years.

Despite the development of newer models, the Agilent 344401A multimeter is still a valuable instrument for both professionals and hobbyists. It is a flexible and trustworthy instrument for numerous industries and applications because of its excellent accuracy, resolution, wide display, and range of measurement modes. In addition, compared to newer versions, it is more affordable since it is available on the used and refurbished market, often still with warranty and calibration certificate. In conclusion, the Agilent 34401A is still worth the purchase for professionals and businesses.

If you’re looking for an Agilent 34401A Multimeter, repair or calibration service, you may contact us or request a quote.

Why Choosing the Right Calibration Service Provider is Crucial

Calibration service is a process that involves comparing the readings or measurements of an instrument or piece of equipment to a known standard in order to assess its accuracy. It is crucial to ensure the reliability and accuracy of the equipment used in whatever industry it may be in. This article will cover topics about who can carry out calibration service and why it's important to choose the right one.

Who can carry out a calibration service?

Calibration can be done by many types of service providers. But, it is recommended to look into important factors to guarantee that the services can be trusted and be done with quality. These include trained and certified technicians, accredited calibration laboratories, and original equipment manufacturers (OEMs).

1. Certified and Trained Technicians

For the calibration of equipment to be correct, trained, and qualified professionals are necessary. These technicians are qualified to perform calibration services because they have received training in a variety of calibration methodologies. The calibration services of a qualified and experienced calibration technician or engineer can guarantee that the instrument is performing effectively and in accordance with OEM specifications and industry requirements.

2. Accredited Calibration Labs

Accredited calibration laboratories have undergone evaluation and have been determined to meet the necessary criteria for technical proficiency and quality. These labs are equipped with the resources and tools needed to offer precise calibration services. The quality and dependability of the calibration results are guaranteed by the traceability of the calibration process to national or international standards.

3. Partnered with Original Equipment Manufacturers (OEMs)

Companies that produce equipment and devices are known as original equipment manufacturers (OEMs). OEMs may offer calibration services for their goods, or they have calibration companies partner with them, just like Micro Precision for example. Experts with in-depth knowledge of the equipment's design and technical requirements perform OEM calibration services. As a result, the calibration services are certain to be precise, dependable, and compliant with industry requirements.

The Importance of Choosing the Right Calibration Service Provider

Choosing a trusted calibration service provider is crucial for ensuring accurate calibration of equipment. Different service providers offer different levels of calibration quality, and choosing the wrong one can lead to inaccurate calibration which can lead to quality concerns. Readings with errors can result in equipment malfunction, safety risks, and impact on productivity and compliance, which are all significant in a business process.

Other Factors to Consider When Choosing a Calibration Service Provider

There are various things to take into consideration while choosing a calibration service provider.

1. Technical expertise and experience

The equipment calibration service provider should have knowledgeable and skilled professionals who are equipped with the technical expertise to carry out the service. They must have a deep understanding of the instrument being calibrated and the process of doing so.

2. Range of services offered

Aside from accreditations and experience, it has a great impact if the provider offers a wide range of services. This shows how broad their knowledge is and the chances that they have more of the necessary equipment and resources that provide precise calibration services are high.

3. Turnaround time and responsiveness

To reduce equipment downtime, the calibration service provider should have a short turnaround time. Additionally, they should be receptive and offer timely updates on the calibration progress.

Quality calibration services are essential for equipment and instruments used in various industries. This ensures accuracy and reliability. Looking into the experience, credentials, and capabilities is important in order to choose the right service provider for your business. It is a tedious decision-making process that's why one should consider if they are certified professionals, are accredited labs, or if they work with OEMs. Once you find a reliable calibration service provider to work with, you've also found a trusted partner in the business that will last.

If you’re looking for a trusted calibration service provider you may contact us or request a quote.

Fluke 189 Multimeter: Your Go-To Tool for Reliability & Precision

It is essential to have a trustworthy multimeter when doing electrical work. Due to its high degree of accuracy, robustness, and practical features, the Fluke 189 multimeter is a well-liked option among professionals in the industry. In this article, we will explore why this device should be at the top of your ‘to consider list’ when buying a digital multimeter.

Precision and Accuracy

The Fluke 189 is a true RMS digital multimeter designed for different applications. This can be used with a wide range of settings which makes it capable of measuring with accuracy. The range of parameters includes voltage, current, resistance, and frequency.

The main characteristics of this equipment are precision and accuracy. The resolution of 50,000 counts and accuracy level of 0.025% DC voltage enable accurate measurements to be made each time. Even in noisy electrical situations, AC voltage and current may be correctly measured because of the true RMS function.

Designed with Durability in Mind

The Fluke 189 Multimeter is designed to withstand different tough work environments. It is capable of functioning without damage even if dropped from up to 1 meter, this makes it a reliable tool in the field. Thanks to its easy-to-read display and ergonomic design, it is an equipment that is simple to use in any situation.

What Makes the Fluke 189 Different?

What Makes the Fluke 189 Different?

This tool is distinguished as a top tool in its field when compared to other multimeters in its category. With a better degree of precision and resolution than other digital multimeters, the Fluke 189 is intended to be more accurate. It is a unique gadget that experts like due to its sturdiness, great specifications, and performance.

Powerful Specs and Features

The Fluke multimeter has advanced features that makes it a favorite go-to by engineers, electricians and technicians. Here are the amazing features that this device holds:

Display:

- 3.5 digital LCD with a maximum reading of 50,000 counts

- Bar graph update rate: 40 times per second

Measurement Range and Accuracy:

- Voltage DC: 500.000 mV to 1000.0 V, ±(0.025%+5) accuracy

- Voltage AC: 500.000 mV to 1000.0 V, ±(0.4%+40) accuracy

- Current DC: 500.00 μA to 10.00 A, ±(0.05%+2) accuracy

- Current AC: 500.00 μA to 10.00 A, ±(0.6%+2) accuracy

- Resistance: 500.00 Ω to 500.00 MΩ, ±(0.05%+2) accuracy

- Capacitance: 50.000 nF to 50.00 mF, ±(1.0%+2) accuracy

- Frequency: 5.000 Hz to 500.0 kHz, ±(0.005%+1) accuracy

Other features:

- True RMS AC voltage and current measurement

- Min/Max/Average recording mode

- 250 μs peak capture

- Auto and manual ranging

- Capacitance 0.01 nF to 50 milliF

- Backlit display for easy reading in low light conditions

- Safety ratings: CAT III 1000V/CAT IV 600V

- Runs on six AA batteries (included) or an AC adapter (not included)

Why do Professionals Buy the Fluke 189?

This tool is praised for its accuracy, dependability, and practical features by professionals who have used it. From vehicle repair to power plant maintenance, the Fluke 189 has been applied in a variety of situations and consistently supplied reliable measurements. Other applications are also within the fields of Electronics, HVAC, Industrial, Automotive and Industrial.

Another factor that buyers have considered is its reliable manufacturer. Fluke, a well-known manufacturer of test and measurement equipment, considers the 189 model as one of its popular devices and part of their top-of-line quality instruments.

Overall, the Fluke 189 Multimeter is a versatile device that has proven over and over again that it is reliable. Accuracy, durability and convenience are its main selling points. This makes it applicable in different fields and preferred by experts due to the precise measurements it delivers.

If you’re looking for a Fluke 189 Multimeter device, repair or calibration service, you may contact us or request a quote.

Understanding Spectrum Analyzers and Their Role in Signal Analysis

In order to fully understand RF(radio frequency) signals, spectrum analyzers, powerful instruments used in signal analysis, are essential. This article will cover the definition, operation, uses, varieties, and comparisons of spectrum analyzers and oscilloscopes.

What is a Spectrum Analyzer?

A spectrum analyzer is an advanced electronic instrument that measures the magnitude of an input signal versus frequency across the entire frequency spectrum covered by the equipment. It records and analyzes a signal's frequency components, giving valuable insights into the spectral content.

How a Spectrum Analyzer Works

A spectrum analyzer uses a series of processes to precisely capture and display the strength of a frequency signal. To remove unwanted interference and noise, the input signal is first amplified and filtered. The time-domain signal is then transformed into a representation of the frequency domain using frequency conversion and signal processing techniques, such as fast Fourier transform (FFT). The transformed data is then displayed on the device, showing the signal's frequency components.

What is a Spectrum Analyzer Used for?

Professionals from different fields and industries have used spectrum analyzers for different applications. They are extensively used in RF analysis and wireless communications to analyze signal quality, find interference, and optimize transmission performances. Aside from that, they are essential for audio and acoustic analysis because they make it possible to measure sound signals accurately and perform spectral shaping and noise analysis. The use of this device in interference analysis and EMC testing is helpful for identifying and mitigating electromagnetic compatible issues. Moreover, they are useful for signal monitoring and troubleshooting, giving engineers the ability to monitor and troubleshoot signal-related issues.

Types of Spectrum Analyzers

There are different types of spectrum analyzers that offer unique features and benefits.

Real-time Spectrum Analyzers (RSA)

They provide immediate, continuous signal analysis, capturing, and real-time data processing. They work well for applications requiring dynamic analysis because they can capture frequently shifting and time-varying signals.

Swept-tuned Spectrum Analyzers (SA)

By sweeping through a certain frequency range and detecting the amplitude of signals at various frequencies, swept-tuned analyzers provide high-frequency accuracy and resolution. They may offer exact measurements for detecting particular frequencies and signal properties and are frequently used for thorough frequency analysis.

Vector Signal Analyzers (VSA)

Spectrum analyzers and vector signal generators' features are combined in vector signal analyzers. They offer a thorough analysis of complex modulated signals, enabling an in-depth examination of elements including amplitude, phase, and modulation quality.

Handheld and Portable Spectrum Analyzers

These analyzers are suited for field applications because of their portability and ease. Engineers and technicians may simply transport them to various locations thanks to their small and light form factors.

Spectrum Analyzer vs. Oscilloscope

Although oscilloscopes and spectrum analyzers are both instruments used for signal analysis, their functions are different. Spectrum analyzers concentrate on frequency analysis and offer a thorough overview of a signal's frequency content. They are perfect for detecting signals with numerous frequency components and finding interference. Oscilloscopes, on the other hand, record and show a signal's voltage waveform in time. They are excellent for evaluating transient events and confirming signal integrity since they are well-suited for examining the signal's amplitude, timing, and shape.

In a nutshell, spectrum analyzers are essential tools for signal analysis because they provide valuable insights into frequency spectrum. Their uses are widespread and include signal monitoring, audio analysis, EMC testing, and wireless communications. Professionals may select the best spectrum analyzer to suit their unique needs by studying its capabilities, applications, and types. Oscilloscopes and spectrum analyzers have separate uses, but they work together to provide comprehensive views of signals in both the frequency and time domains. Engineers and technicians can improve signal performance, address problems, and guarantee dependable and effective communication systems by utilizing the power of spectrum analysis.

If you’re looking into renting or purchasing a spectrum analyzer or needing a calibration and repair service, you may contact us to learn more.

Immediate Calibration

Immediate Calibration

What Makes the Fluke 189 Different?

What Makes the Fluke 189 Different?