Semiconductor Wafer Thickness & Precision Step Height Analysis

Micro Precision uses state of the art technology to perform semiconductor wafer thickness and step height analysis by incorporating accredited ellipsometry and surface profiling methodologies. Our laboratory in Richardson, TX is accredited by ANAB to perform ISO/IEC 17025-2017 accredited measurements.

Wafer thickness and step height analysis are critical components used in the semiconductor industry.

What is an ellipsometer?

The VASE® variable angle spectroscopic ellipsometer features computer-controlled wavelength and angle of incidence selection. A Xenon lamp supplies light from the ultraviolet (UV) to the near infrared (NIR). Individual wavelengths are selected with a double-chamber monochromator. A stacked Si/InGaAs detector is used from 193nm to 1700nm. Recent development of an extended InGaAs detector allows measurement to 2500nm. The VASE® uses a rotating analyzer ellipsometer (RAE) configuration with the addition of JJ Woolam’s patented AutoRetarder™

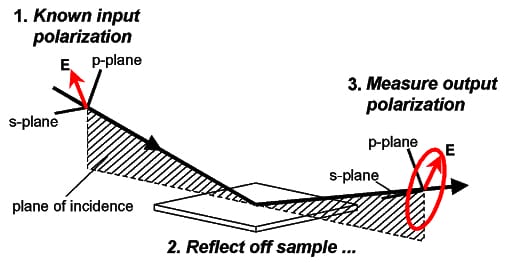

Defining Ellipsometry:

Ellipsometry is the use of polarized light to characterize thin film and bulk materials. A change in polarization is measured after reflecting light from the surface. Thin film thickness (t) and optical constants (n, k) are derived from the measurement.

Information is obtained from each layer interacting with the measurement. Light returning from the film–substrate interface interferes with the surface reflection to provide layer information.

Accredited Step Height Analysis Capabilities

Stylus profilers and surface standards:

Stylus profilers are versatile measurement tools for the study of surface topography. The profiler relies on a small-diameter metal stylus with a diamond or composite material tip that scans the surface of the sample. During the scan, the stylus makes direct contact with the surface to obtain data with very high precision and repeatability. The stylus profiler stage moves the sample linearly under the stylus to obtain measurements of the surface profile. As it encounters surface features, the stylus moves vertically to measure the various features.

New advances in stylus profiler technology have been developed for shrinking geometries. They include a Low Inertia Sensor for unparalleled step height repeatability. Incorporation of software enhancements and program leveling functions ensure consistent accurate measurement with minimal uncertainty.

Precision step height calibration:

Measurement capability is set up with the use of a surface profile system, which in conjunction with NIST referenced and traceable standards are used to measure overall step height profile.

Dektak 3®

Surface profiler with 6.5″ sample vacuum stage, 3″x6″ XY sample translation, manual stage, 1A vertical resolution, 131um maximum vertical range, 50um to 50mm scan length, maximum 8,000 points per scan, 1mg-40mg programmable stylus force range.

Semiconductor Wafer & Step Height Capabilities

ANAB Accredited to ISO/IEC 17025-2017 Accredited capability:

- Semiconductor Wafer Thickness Standards

- Semiconductor Precision Step Height

| Parameter / Equipment | Range | Expanded Uncertainty of Measurement (+/-) | Accredited (ISO/IEC 17025, Z540.3) |

|---|---|---|---|

| Wafer Thickness | (3.0 to 1500)nm | 0.32nm | Ellipsometer and Standard Wafers |

| Precision Step Height Standards | (100 to 1000)A (>1 to 250)kA | 17A | Surface Profiler and Standard Step |

Other Capabilities

Micro Precision can perform instrument calibration services on equipment from variety of applications for specific industries and lines of business. If you have a calibration need that is not listed in this area, please contact us.

Laboratory Standards

Calibration laboratory standards are critical for your organization’s most accurate measurements.

Optical

Micro Precision accredited optical, light, and fiber optic calibration lab services.

Chemical

Micro Precision accredited thermodynamic & chemical calibration lab services with temperature, humidity, life science, and pharma capabilities.

RF - Microwave

Micro Precision accredited RF & microwave calibration lab services.

Electrical

Micro Precision accredited electrical calibration lab services with multimeter, multifunction calibrator, oscilloscope, and power supply capabilities.

Mechanical & Dimensional

Micro Precision accredited mechanical and dimensional calibration lab services with pressure, torque, force, flow, velocity, and aircraft jack load capabilities.

Request A Quote

"*" indicates required fields

Service Area

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

2165 N. Glassell St. Orange CA 92865

or you can contact us via phone at

(714) 901-5659

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

22835 Industrial Place Grass Valley CA 95949

or you can contact us via phone at

(530) 268-1860

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

Calle Paraiso No. 1596 esq. Tabachin, Colonia del fresno Guadalajara, Jalisco 44900

or you can contact us via phone at

52 33 1811 0955

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

Carretera San Luis Rio Colorado KM 10.5 Locales 13 y 14 Parque Industrial las Californias,Mexicali, Baja California Mexicali, B.C. 21394

or you can contact us via phone at

(686) 592-1605

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

ALVARO OBREGON No. 252, int. 1 Silao Guanajuato, Mexico

or you can contact us via phone at

52 472 108 9257

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

Block 2 Lot 4 Calamba Premiere International Park (CPIP) DPL Technology Building, Brgy. Batino, Calamba City Laguna, Philippines 4027

or you can contact us via phone at

63 49 5023015

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

7877 SW Cirrus Drive Beaverton, OR 97008

or you can contact us via phone at

(503) 746-5845

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

9080 Activity Road, Suite C San Diego CA 92126

or you can contact us via phone at

(858) 547-0217

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

6878 Santa Teresa Blvd San Jose CA 95119

or you can contact us via phone at

(408) 937 6600

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

413 Bondstreet Road, Bangpood Subdistrict, Pakkred District Nonthaburi, Thailand 11120

or you can contact us via phone at

66 2 583 9834

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

11451 US-301 #105 Thonotosassa Florida 33592

or you can contact us via phone at

(813) 621-6495

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

Street No. 11 Gate 74 Salwa Industrial Area Doha, Qatar

or you can contact us via phone at

+974 44607669

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

201, 2nd Sacom Chipsang Bldg. Saigon High-Tech Park District 9, HCMC, Vietnam

or you can contact us via phone at

84 28 5448 2008

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

6, Jalan Kelisa Emas, Taman Kelisa Seberang Jaya Penang Malaysia 13600

or you can contact us via phone at

603 3322 1221

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

670 International Parkway Ste 100 Richardson Dallas, Texas 75081

or you can contact us via phone at

(972) 437-6700

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

BLOCK 5008 ANG MO KIO AVENUE 5 #07-02/03 TECHPLACE II SINGAPORE 569874

or you can contact us via phone at

65 6748 4384

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

17072 Tye St. SE Suite #170 Monroe WA 98272

or you can contact us via phone at

(425) 821-0902

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

9831 S. 51st. St. Suite# C-108 Phoenix AZ 85044

or you can contact us via phone at

(480) 361-7246

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

AV. LAS BRISAS NO. 15808 COL. LAS BRISAS TIJUANA, B.C. 22115

or you can contact us via phone at

52 664 331 6909

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

NEW NO. 57 OLD NO. 65, AVADI ROAD, SIPPOY LANE KARAYANCHAVADI POONAMALLEE CHENNAI INDIA 600056

or you can contact us via phone at

91 44 43836089

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

#3-504 Acehightechcity, 775 Gyeongin-ro, Yeongdeungpo-gu Seoul, Korea 150-972

or you can contact us via phone at

82 10 2611-0693

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

3570 Commerce Drive Columbus IN 47201

or you can contact us via phone at

(812) 372-7969

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

2590 Oakmont Drive Suite 310 Round Rock TX

or you can contact us via phone at

(512) 735-9967

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

Av. Nacional No.3, Col. Ejidos de San Crist Ecatepec de Morelos, Estado de Mexico Mexico

or you can contact us via phone at

55 111 56191

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

Kerkenbos, Building no. 1103C Nijmegen 6546 BC

or you can contact us via phone at

31 24 763 4000

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

Unit 201, iMEZ Bldg., Pueblo Verde, Osmena St. Basak, Lapu-Lapu City Cebu, Philippines

or you can contact us via phone at

032 234 3643

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

12071 Tejon Street Suite # 100 Westminster, Colorado 80234

or you can contact us via phone at

(720) 535-4470

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

Benzstra M Germany 82178

or you can contact us via phone at

49 89 638 587 37

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

16 Columbia Dr, Amherst, NH 03031

or you can contact us via phone at

(978) 226-5601

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

201, 2nd Sacom Chipsang Bldg. Saigon High-Tech Park District 9, HCMC, Vietnam

or you can contact us via phone at

84 937 825 507

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

1405 Potter Drive Colorado Springs CO 80909

or you can contact us via phone at

(719) 442-0004

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

1100 Athens Ave. Suite A Richmond VA 23227

or you can contact us via phone at

(804) 728-3656

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

8847 Long Street Lenexa KS 66215

or you can contact us via phone at

913-541-0629

or email us at [email protected]

GET DIRECTIONS

Looking for something else?