Mechanical

Micro Precision is a leading provider of calibration for mechanical and electro-mechanical equipment. These service are provided to a wide range of industries around the globe. At Micro Precision, we know your research and production equipment is mission-critical, and that’s why we treat each piece with exacting precision and ISO-accredited quality. Our ISO/IEC 17025:2017 scope of accreditation covers calibration of mechanical and electro-mechanical tools.

Calibrations are always performed in accordance with manufacturers specifications. We service a wide range of customers from the aerospace and automotive industries to semiconductor manufacturers and pharmaceutical companies. Some of the items we calibrate are magnehelic, force gages, weighing devices, compression, torque, pressure gages, oxygen and hydraulic dials, high accuracy pressure calibrators, strain gages, load cells, transducers, vacuum gages, low-level capacitance diaphragms, transducers, flow instruments (liquid & gas), and velocity calibration from 100 to 7,000 feet per minute.

Instrument manufacturers calibrated:

Ashcroft, Crystal Engineering, Druck, Dwyer, Fluke, GE, Heise, Norbar, Sturtevant Richmont, Meriam, Noshok, Rosemount, Ruska, TSI, Vaisala, WIKA, CDI, Snap-on, Omega, Sierra, Dwyer, and more…

Unmatched Expertise

Micro precision uses state of the art equipment to ensure the highest degree of measurement accuracy. With this equipment, and the expertise of our technicians, we are able to offer you the best possible turnaround time, and pricing in the industry for your mechanical and electro-mechanical calibration needs.

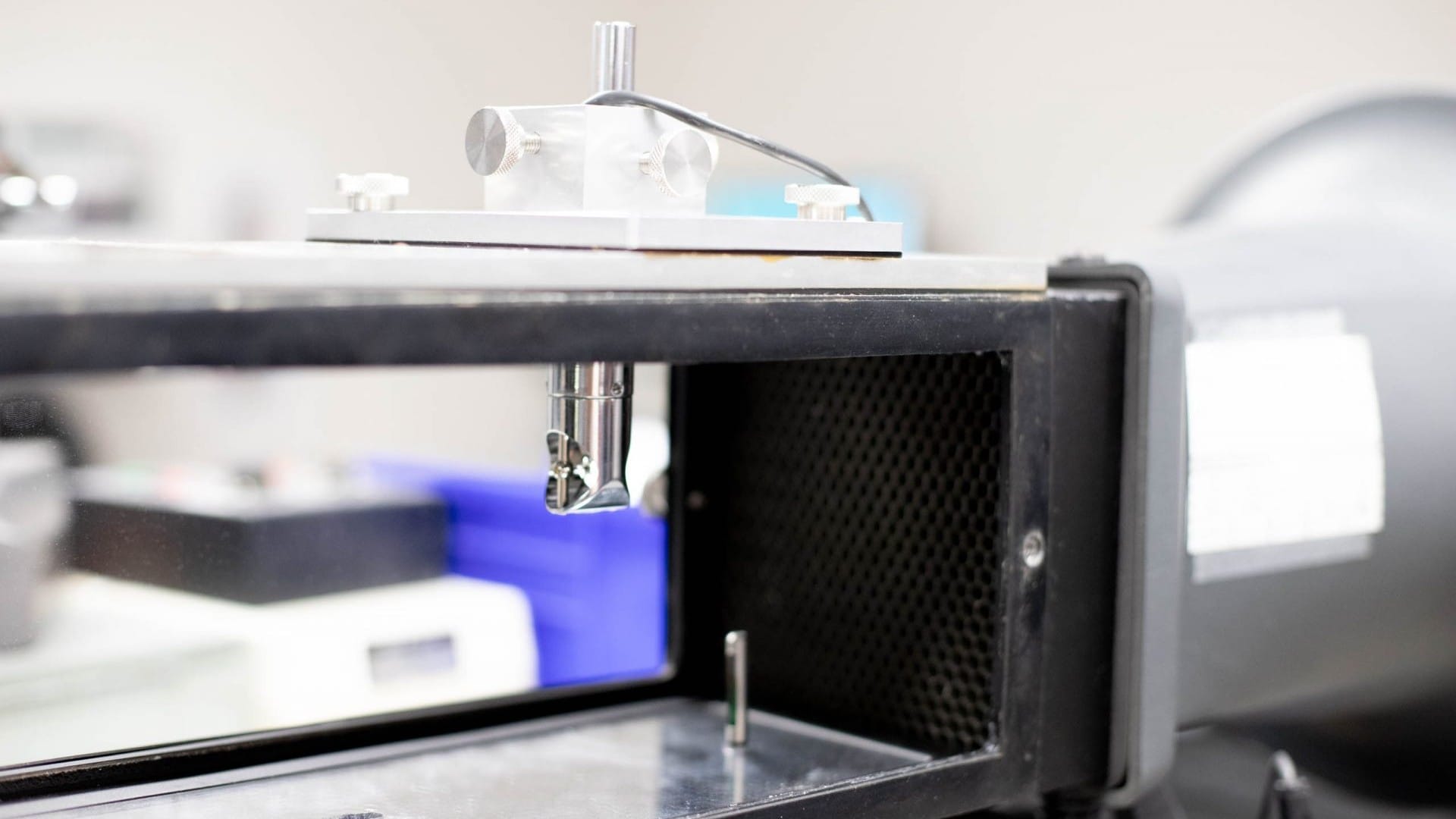

Dimensional

Micro Precision’s ISO 17025:2017 dimensional calibration services verify all your measuring instruments and provide reliable, accurate, and traceable measurement results. Our quality instrument calibration capabilities are designed to reduce risk and inaccuracies in your measurements.

Instrument manufacturers calibrated:

Brown & Sharpe, Deltronic, Fisher, Fowler, Glastonbury Gage, Hemco, JS Technology, Mahr, Mercury Gage, Meyer, Mitutoyo, NSK, Rahn, Scherr-Tumico, Sheffield, SPI, Southern Gage, Starrett, Tesa, Van Keuren, Vermont Gage, and more…

Endless range of equipment capabilities

Dimensional items include micrometers, calipers, gages, and tapes, as well as, high-end optics-systems, comparators, and coordinate measuring machines (CMM). Our primary dimensional laboratory has capabilities of surface flatness and roughness testers, gage blocks, cylindrical rings, and thread gages.

Pressure

We understand that precise and accurate pressure measurements are essential to our customers’ in-process safety, compliance, and management efficiency. Our absolute pressure, gage pressure, and low pressure vacuum capabilities are ISO/IEC 17025-2005 accredited, and whether we’re calibrating your pressure transmitters, deadweight testers, pressure gauges, or transducers, you can be assured that our hydraulic and pneumatic pressure calibrations will be performed with true SI unit traceability through NIST. Our pressure and vacuum calibrations are also ISO 9001 calibration-compliant, performed by our highly-trained technical staff and industry-renowned metrology and quality experts.

Types of instruments calibrated:

Compound Gage, Dead Weight Tester, Master Pressure Gage, Pressure Controller, Pressure Gage, Pressure Indicator, Pressure Transducer, Pressure Transmitter, Pressure Valve, and more…

Micro Precision can meet all customer requirements with accurate and repeatable measurements you can count on. We calibrate a wide range of pressure devices. Our capabilities range from -14.7 to 50,000 psi.

We are ready to meet all your needs from analog pressure gages to high end pressure transducers; digital pressure standards and deadweight testers.

Our full range of pressure capabilities are included in our ISO 17025 Scope of Accreditation

For pressures .2 to 1000 PSI, Micro Precision uses the Ruska 2465 Gas Piston Gauge.

This has a long history of serving national standards laboratories, commercial industry and government organizations as a primary pressure standard.

The Ruska 2465 provides the capability of generating pressures to within a total expanded uncertainty of 10 ppm to 700 kPa (100 psi) and 26 ppm to 7 MPa (1000 psi).

For pressures up to 12000 PSI, Micro Precision uses the Ruska2400 Dead Weight Tester. This was designed as a laboratory reference of pressure.

High operating range and mechanical durability are features that have been made possible by the use of a secondary piston of relatively large diameter. Micro Precision utilizes a Gas Pressure Booster in conjunction for calibrating gas gages.

For Pressure up to 50000 PSI, Micro Precision uses a Pressure Comparison System, which is capable of generating hydraulic pressures up to 50,000psi at an accuracy of +/- 0.2% of reading.

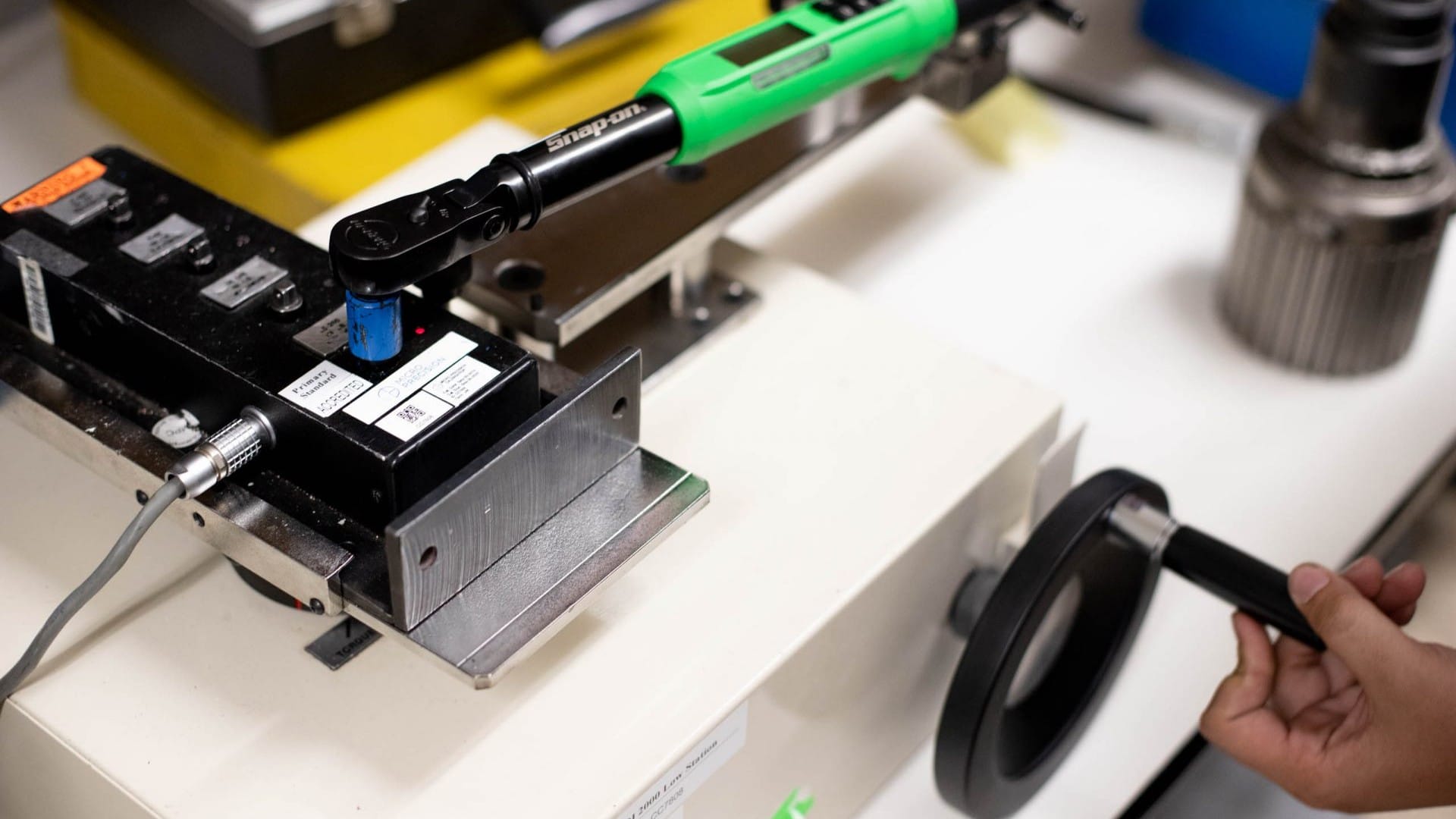

Torque

Torque wrenches are used in several industries. Automotive, aviation, semiconductor, manufacturing and nuclear. Torque wrench calibration is critical for all processes, from on the manufacturing floor, to aircraft servicing and maintenance. Micro Precision’s CDI Torque Multitest Premier Calibration System allows us to perform hands-free calibrations on Torque Wrenches up to 2000 ft/lbs. as well as Tensiometers/Cable Tension Meters all with a single standard.

We also calibrate Torque Multipliers up to 20,000 ft/lbs. using our Master Torque Tester. Micro Precision offers a wide range of torque calibrations.

Mountz Torque Preferred Calibration Providers

Torque equipment calibrated:

Dial Torque Wrench, Digital Torque Gage, Digital Torque Tester, Torque Analyzer, Torque Arm, Torque Calibrator, Torque Driver, Torque Gage, Torque Gun, Torque Handle, Torque Indicator, Torque Limiter, Torque Meter, Torque Multiplier, Torque Screwdriver, Torque Sensor, Torque Standard, Torque Tester, Torque Transducer, Torque Watch

Torque Wrench Specifications

All torque wrenches fall into different categories based upon style of the manufacturer, Click Style, Beam, Digital, or Dial Style Torque Wrench.

The actual “Click” from a wrench is considered a “Cycle” of that wrench. Most manufacturers recommend click-style torque wrench calibration after-5000-cycles. For most customers, this means you should calibrate and test torque wrenches every 12 months.

Mass

Our Mass calibration labs are designed and constructed to meet the recommended environmental and procedural practices as detailed by the National Institute of Technology (NIST).

Our capabilities range from Class 1 to Class 7, 1mg to 100kg, which give us a wide range of services to offer our clients. Our labs have been accredited to ISO/IEC 17025 for mass calibration which ensures we meet your calibration quality requirements.

Instrument manufacturers calibrated:

Denver Instrument, INSCO, Rice Lake, Troemner, Ohaus, Mettler, Toledo, and more…

Weight Calibration

Micro Precision’s Mass Standard calibration laboratories have stringent environmental controls. We ensure all weights are provided an adequate temperature stabilization period which allows them to acclimate to the surrounding lab environment.

Our Mass calibration labs are equipped with marble tables for the lab comparators. This helps reduce vibrations. Micro Precision utilizes certified test weights to perform modified single and double substitution calibration verifications. With traceability through national laboratories we provide accurate and repeatable calibration services which will meet all quality requirements.

Force

Using state-of-the-art master load cells and dead weights, Micro Precision can provide tension calibration services up to 400,000 lbf, and compression calibration up to 3,000,000 lbf. We also provide custom fixtures and load cell calibration services for machines in your facility, to help accommodate your calibration needs.

Instrument manufacturers calibrated:

Tinius Olsen, Instron, HBM, Chatillon, Sensotec, Shimadzu, Admet, Lloyd, Thwing-Albert, Forney, Humboldt, Test-Mark, and more…

Get Started

Start your request today to have one of our calibration specialists perform a force equipment calibration, repair, or validation service.

Flow

Flowmeters are a critical part of testing and measurements used in a wide variety of applications where accurate flow measurements are essential. Equipment calibration applications include (but are not limited to) HVAC, energy and utilities, water management, aerospace, agriculture and the pharmaceutical industry. Regular calibrations assure you that the flowmeter’s measurements are as accurate as their specifications say they are.

Flow meter calibration:

Coriolis Flow Meter, Electromagnetic Flow Meter, Gas Flow Meter, Laminar Flow Meter, Liquid Flow Meter, Magnetic Flow Meter, Optical Flow Meter, Paddle Wheel Flow Meter, Rotometer Flow, Thermal Mass Flow Meter, Turbine Flow Meter, Ultrasonic Flow Gauge, Velocity Meter, Venturi Meter Flow, Viscosity Cup \ Viscosity Meter, Vortex Flow Meter

Calibration Specifics

Using the flow calibration system, we perform high accuracy gas flow device calibrations in the range of 0.05 – 3000 LPM to an accuracy of 0.6% of reading.

Water Flow Calibration uses a high accuracy flow calibration system able to generate 0 to 300 gpm at .1% accuracy using Endress + Hauser Coriolis Flow Meter.

Velocity

Micro Precision has the capability of performing 17025 accredited air velocity calibrations of anemometers and other wind speed indicators.

Our wind tunnel has a range of 100 to 7,000 feet per minute and has an accuracy of plus or minus 2% of reading. This wind tunnel is designed to calibrate rotary vane type, ultrasonic anemometers and hot wire type anemometers.

Velocity calibrations performed:

Air Velocity, Anemometer, Hot Wire Anemometer, Rotary Vane, Ultrasonic Anemometer, Velocity

Air Velocity Wind Tunnel

The wind tunnel will allow us to offer accredited calibrations for a variety of air velocity instruments including rotary and hot wire anemometers, balometers, wind speed indicators and more.

Aircraft Jack Proof Load

With our on-site proof load testing, you save money, reduce downtime, and eliminate the hassles of shipping your aircraft bipod, tripod, and quadruped jacks. Testing capabilities for aircraft jacks, single-stage, multi-stage, and axle jacks with capacity of up to 75,000lbs, ensures we are able to test a wide range of aircraft jacks from many different manufacturers.

Aircraft Jack Calibration:

Bipod Jacks. Tripod Jacks. Quadrupod Jacks

Get Started

Start your request today to have one of our calibration specialists perform an on-site proof load service of your aircraft jacks.

Additional Services

In addition, our mechanical and electro-mechanical calibration services include:

- Balances

- Durometers

- EFD’s

- Force Gages (Compression and Tension)

- Hardness Testers

- Load Cells

- Magnehelic Gages

- Manometers

- Pressure Gauges

- Pressure Transducers

- Pull Testers

- Scales

- Torque (Drivers, Transducers, Watches and Wrenches)

- Vacuum Gauges

- Vacuum Transducers

- Viscometers

- Weights

- Flow

- and more…

Other Capabilities

Micro Precision can perform instrument calibration services on equipment from variety of applications for specific industries and lines of business. If you have a calibration need that is not listed in this area, please contact us.

Laboratory Standards

Calibration laboratory standards are critical for your organization’s most accurate measurements.

Optical

Micro Precision accredited optical, light, and fiber optic calibration lab services.

Chemical

Micro Precision accredited thermodynamic & chemical calibration lab services with temperature, humidity, life science, and pharma capabilities.

RF - Microwave

Micro Precision accredited RF & microwave calibration lab services.

Electrical

Micro Precision accredited electrical calibration lab services with multimeter, multifunction calibrator, oscilloscope, and power supply capabilities.

Semiconductor

ANAB Accredited to ISO/IEC 17025-2017 Accredited semiconductor wafer thickness and precision step hight calibration.

Request A Quote

"*" indicates required fields

Service Area

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

2165 N. Glassell St. Orange CA 92865

or you can contact us via phone at

(714) 901-5659

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

22835 Industrial Place Grass Valley CA 95949

or you can contact us via phone at

(530) 268-1860

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

Calle Paraiso No. 1596 esq. Tabachin, Colonia del fresno Guadalajara, Jalisco 44900

or you can contact us via phone at

52 33 1811 0955

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

Carretera San Luis Rio Colorado KM 10.5 Locales 13 y 14 Parque Industrial las Californias,Mexicali, Baja California Mexicali, B.C. 21394

or you can contact us via phone at

(686) 592-1605

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

ALVARO OBREGON No. 252, int. 1 Silao Guanajuato, Mexico

or you can contact us via phone at

52 472 108 9257

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

Block 2 Lot 4 Calamba Premiere International Park (CPIP) DPL Technology Building, Brgy. Batino, Calamba City Laguna, Philippines 4027

or you can contact us via phone at

63 49 5023015

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

7877 SW Cirrus Drive Beaverton, OR 97008

or you can contact us via phone at

(503) 746-5845

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

9080 Activity Road, Suite C San Diego CA 92126

or you can contact us via phone at

(858) 547-0217

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

6878 Santa Teresa Blvd San Jose CA 95119

or you can contact us via phone at

(408) 937 6600

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

413 Bondstreet Road, Bangpood Subdistrict, Pakkred District Nonthaburi, Thailand 11120

or you can contact us via phone at

66 2 583 9834

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

11451 US-301 #105 Thonotosassa Florida 33592

or you can contact us via phone at

(813) 621-6495

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

Street No. 11 Gate 74 Salwa Industrial Area Doha, Qatar

or you can contact us via phone at

+974 44607669

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

201, 2nd Sacom Chipsang Bldg. Saigon High-Tech Park District 9, HCMC, Vietnam

or you can contact us via phone at

84 28 5448 2008

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

6, Jalan Kelisa Emas, Taman Kelisa Seberang Jaya Penang Malaysia 13600

or you can contact us via phone at

603 3322 1221

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

670 International Parkway Ste 100 Richardson Dallas, Texas 75081

or you can contact us via phone at

(972) 437-6700

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

BLOCK 5008 ANG MO KIO AVENUE 5 #07-02/03 TECHPLACE II SINGAPORE 569874

or you can contact us via phone at

65 6748 4384

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

17072 Tye St. SE Suite #170 Monroe WA 98272

or you can contact us via phone at

(425) 821-0902

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

9831 S. 51st. St. Suite# C-108 Phoenix AZ 85044

or you can contact us via phone at

(480) 361-7246

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

AV. LAS BRISAS NO. 15808 COL. LAS BRISAS TIJUANA, B.C. 22115

or you can contact us via phone at

52 664 331 6909

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

NEW NO. 57 OLD NO. 65, AVADI ROAD, SIPPOY LANE KARAYANCHAVADI POONAMALLEE CHENNAI INDIA 600056

or you can contact us via phone at

91 44 43836089

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

#3-504 Acehightechcity, 775 Gyeongin-ro, Yeongdeungpo-gu Seoul, Korea 150-972

or you can contact us via phone at

82 10 2611-0693

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

3570 Commerce Drive Columbus IN 47201

or you can contact us via phone at

(812) 372-7969

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

2590 Oakmont Drive Suite 310 Round Rock TX

or you can contact us via phone at

(512) 735-9967

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

Av. Nacional No.3, Col. Ejidos de San Crist Ecatepec de Morelos, Estado de Mexico Mexico

or you can contact us via phone at

+55 111 56191

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

Kerkenbos, Building no. 1103C Nijmegen 6546 BC

or you can contact us via phone at

31 24 763 4000

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

Unit 201, iMEZ Bldg., Pueblo Verde, Osmena St. Basak, Lapu-Lapu City Cebu, Philippines

or you can contact us via phone at

032 234 3643

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

12071 Tejon Street Suite # 100 Westminster, Colorado 80234

or you can contact us via phone at

(720) 535-4470

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

16 Columbia Dr, Amherst, NH 03031

or you can contact us via phone at

(978) 226-5601

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

201, 2nd Sacom Chipsang Bldg. Saigon High-Tech Park District 9, HCMC, Vietnam

or you can contact us via phone at

84 937 825 507

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

1405 Potter Drive Colorado Springs CO 80909

or you can contact us via phone at

(719) 442-0004

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

1100 Athens Ave. Suite A Richmond VA 23227

or you can contact us via phone at

(804) 728-3656

or email us at [email protected]

GET DIRECTIONS

If you have any inquiries, recommendations, or simply wish to connect with us, we’d love to hear from you! Please don’t hesitate to reach out to us at

8847 Long Street Lenexa KS 66215

or you can contact us via phone at

913-541-0629

or email us at [email protected]

GET DIRECTIONS

Looking for something else?